Male Pipe Weld Connector RCW

➯ The connector's precise threading and weldability guarantee a tight seal, minimizing the risk of leakage and ensuring optimal system performance.

➯ The Male Pipe Weld Connector (RCW) is a robust fitting designed to facilitate a leak-proof connection between a male pipe thread and a welded tube end.

➯ Its construction ensures high durability and resistance to corrosion, making it suitable for demanding environments such as oil and gas, chemical processing, and hydraulic systems.

➯ This connector is meticulously engineered to withstand high pressure, temperature variations, and corrosive environments, ensuring reliable performance even in the most demanding conditions.

➯ The Male Pipe Weld Connector RCW is a critical component in tube fitting systems. It is designed to provide a secure and leak-free connection between tubes and pipes in various industrial applications.

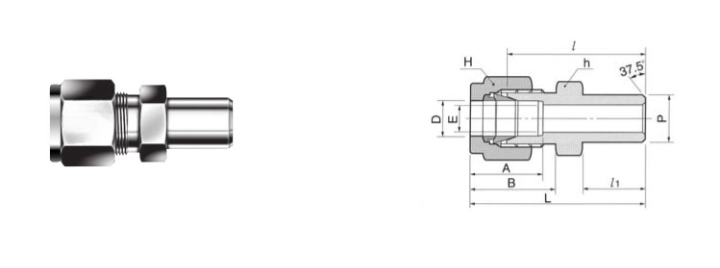

↪ Precision Machining: Each connector undergoes precision machining processes to achieve tight tolerances and smooth surface finishes. This precision ensures a perfect fit and enhances the tubing system's overall performance.

↪ Male Pipe Thread: One end of the connector is equipped with male pipe threads, enabling easy connection to female-threaded components such as valves, fittings, or other piping systems. The standardized threading ensures compatibility and facilitates efficient assembly.

↪ Weld End Design: The Male Pipe Weld Connector RCW features a weld end design, allowing for seamless integration with pipes through welding processes. This design eliminates the need for additional fittings or adapters, simplifying installation and reducing potential leak points.

↪ Robust Construction: Manufactured from high-quality materials such as stainless steel, carbon steel, or other alloys, the Male Pipe Weld Connector RCW boasts exceptional strength and durability. This robust construction ensures long-term integrity and resistance to wear and tear.

↪ Leak-Free Sealing: The connector is engineered with precision-engineered sealing mechanisms, such as O-rings or gaskets, to provide a reliable and leak-free seal between the connector and mating components. It ensures the integrity of the fluid or gas flow within the tubing system.

↪ Corrosion Resistance: To withstand corrosive environments and harsh operating conditions, the connector is often coated with corrosion-resistant materials or finishes. This protective layer enhances the longevity of the connector and ensures consistent performance in challenging environments.

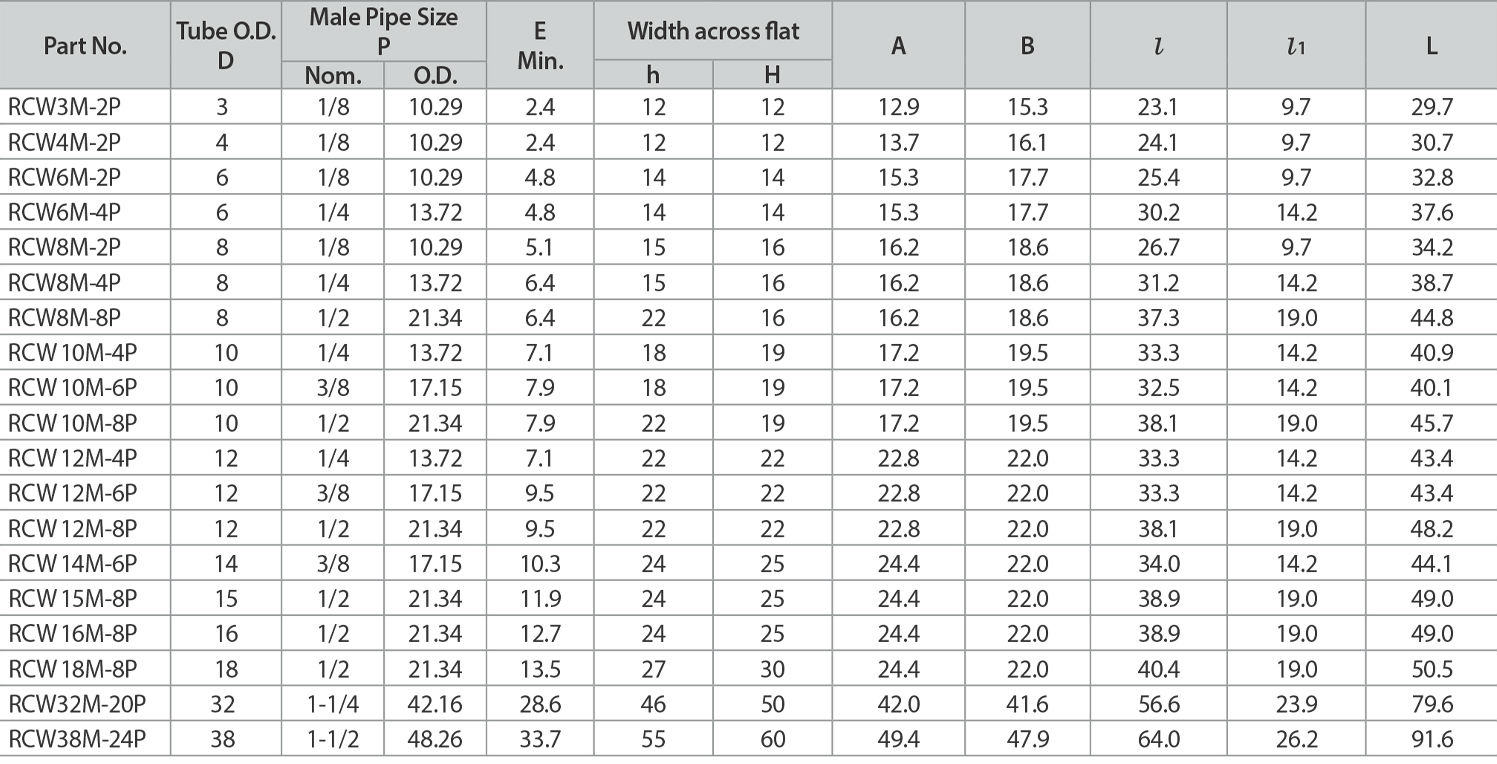

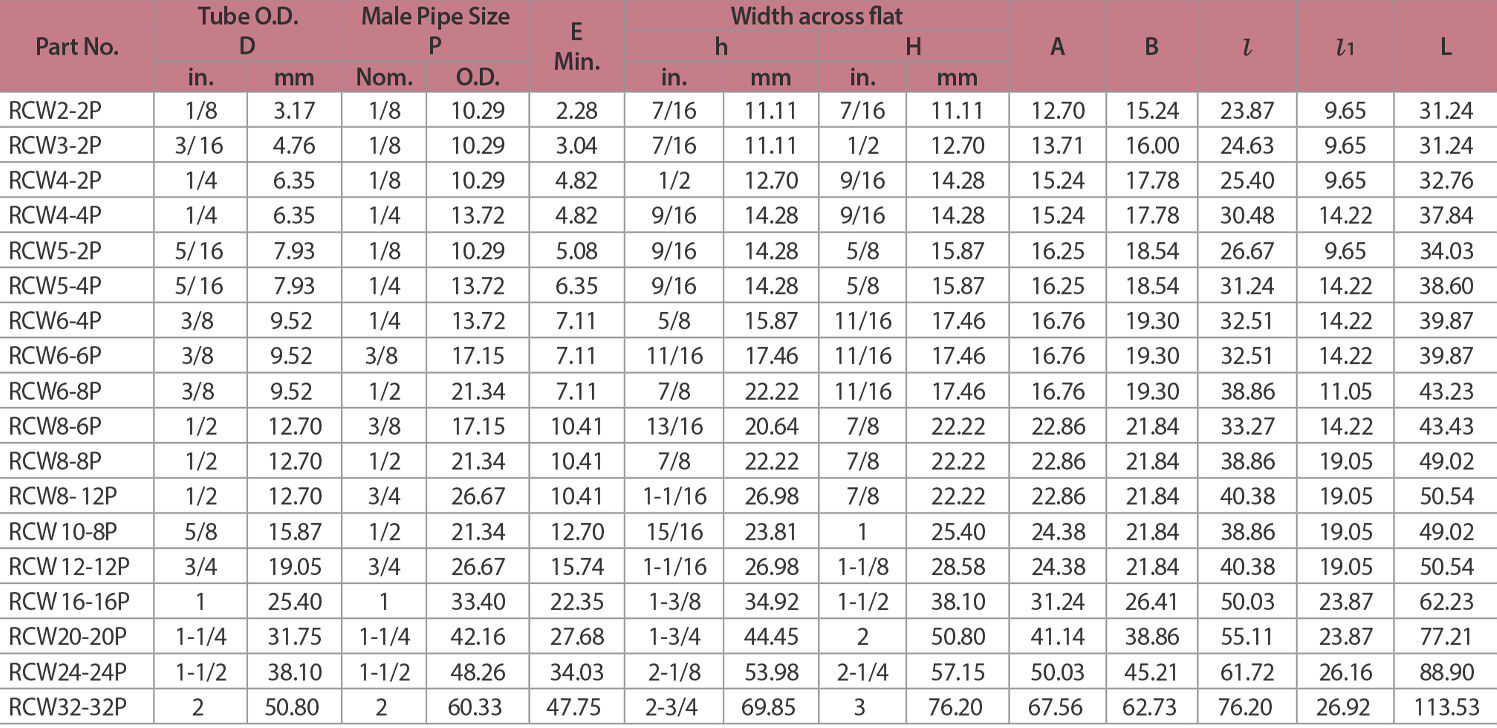

↪ Wide Range of Sizes and Configurations: The Male Pipe Weld Connector RCW is available in a variety of sizes and configurations to accommodate different tube diameters, wall thicknesses, and application requirements. This versatility makes it suitable for use in various industries, including oil and gas, petrochemicals, chemical processing, power generation, and more.

Connects fractional tube to pipe

Applications:

➢ Aerospace: Hydraulic and pneumatic systems.➢ Automotive: Fuel delivery systems, hydraulic systems.

➢ Food and Beverage: Processing and packaging machinery.

➢ Oil and Gas: Pipeline systems, refineries, offshore platforms.

➢ Pharmaceutical: Processing equipment, cleanroom environments.

➢ Power Generation: Power plants, steam systems, cooling circuits.

➢ Petrochemical: Chemical processing plants and storage facilities.

Connects metric tube to pipe