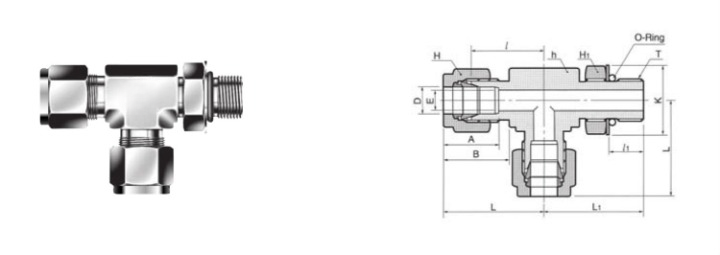

Positionable SAE Male Run Tee RTRS-UP

Positionable SAE Male Run Tee RTRS-UP

➯ The "Positionable SAE Male Run Tee RTRS-UP" is a type of hydraulic fitting that's commonly used in fluid power systems.

➢ RTRS-UP: This part of the identifier likely represents a specific product series, model, or manufacturer's designation for the fitting. It may denote variations such as size, material, or special features within a product line.

➢ Run Tee: "Run Tee" refers to the shape of the fitting. A run tee has three ports, with one port perpendicular to the other two. This configuration allows for branching off a main line while maintaining a continuous flow through the main line.

➢ SAE Male: The term "SAE" stands for the Society of Automotive Engineers, which sets standards for hydraulic fittings and other components used in fluid power systems. "Male" indicates that the fitting has external threads that screw into a corresponding female port or fitting.

➢ Sealing: Proper sealing is crucial to prevent leaks in hydraulic systems. These fittings may incorporate sealing features such as O-rings, gaskets, or cone seats to ensure a secure and leak-free connection.

➢ Materials: These fittings are typically constructed from steel, stainless steel, brass, or aluminium, chosen based on factors such as compatibility with hydraulic fluids, operating pressure, temperature, and environmental conditions.

➢ Positionable: This indicates that the fitting can be adjusted or positioned after installation. This feature allows for flexibility in the orientation of connected components, facilitating precise alignment and efficient routing of hydraulic lines.

➢ Applications: Positionable SAE Male Run Tee fittings are commonly used in hydraulic systems where branching of fluid lines is required. They allow for the connection of three hydraulic lines while providing the flexibility to adjust the orientation of the tee fitting as needed.

➢ Positionable SAE Male Run Tee: This fitting allows for the connection of three hydraulic lines, with one port perpendicular to the other two. It provides the flexibility to adjust the orientation of the tee fitting as needed, facilitating precise alignment and efficient routing of hydraulic lines.

➢ Swivel Run Tee Fittings: Similar to the positionable run tee fittings, swivel run tee fittings offer rotation at the joint, providing flexibility in hose or tubing orientation.

➢ Hydraulic Couplings: Couplings provide quick-connect and disconnect functionality for hydraulic systems. Run tee couplings may be available for applications requiring the branching of hydraulic lines.

➢ Hydraulic Adapters: These fittings allow connections between different types of threads or sizes. For example, an adapter might enable you to connect a male SAE fitting to a female NPT (National Pipe Thread) working on a run-tee configuration.

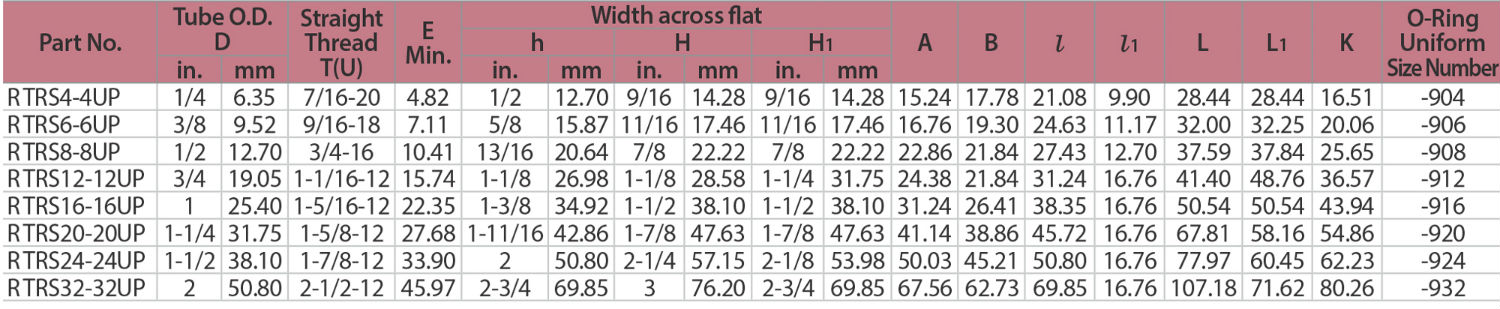

Joining a fractional tube to an SAE straight thread boss

➯ "Positionable SAE Male Run Tee RTRS-UP" fitting comes in various sizes to accommodate different hydraulic system requirements. Standard dimensions for SAE male fittings include 1/8", 1/4", 3/8", 1/2", 3/4", 1", and larger diameters, typically measured in inches. Metric sizes such as M6, M8, M10, M12, M16, etc., may also be available, especially in international markets.

➢ Bulkhead Run Tee Fittings: These fittings are designed for installation through panels or walls. They provide a sealed connection on both sides and a run-tee configuration for routing hydraulic lines.

➢ Banjo Fittings: Banjo fittings feature a hollow bolt with a hose connection perpendicular to the bolt axis, often used in automotive and hydraulic applications. Banjo fittings with SAE male threads on a run tee configuration may be available.

➢ Maintenance: Regular inspection and maintenance of positionable straight thread fittings are necessary to ensure optimal performance and reliability. This includes checking for leaks, inspecting for wear or damage, and replacing any worn or damaged components as needed.

➢ Materials: These fittings are commonly made from brass, stainless steel, or various types of plastics, depending on the application requirements. The choice of material is based on factors such as compatibility with the fluid being conveyed, pressure, temperature, and environmental conditions.