Positionable Straight Thread

↪ These fittings allow for the adjustment or positioning of the connected components while maintaining a sealed relationship.

↪ Positionable straight-thread fittings are components used in fluid and pneumatic systems to create connections between tubes or hoses.

Products:

↪ Swivel Elbows: Used to change the direction of tubing or hose connections while allowing for rotational adjustment.

↪ Swivel Tees: Provide a T-shaped connection with one swivel end, allowing for flexibility in tubing or hose orientation.

↪ Swivel Adapters: Enable connection between different thread types or sizes while allowing for rotational adjustment.

↪ Articulated Fittings: Offer multiple points of articulation, allowing for complex adjustments or positioning in confined spaces.

↪ Adjustable Angle Fittings: These allow for adjustable angles between connected components, providing flexibility in system design and installation.

↪ Union Fittings: are used to join two tubes or hoses with a straight-through connection, often with one or both ends swivelling for adjustment.

↪ Bulkhead Fittings: These fittings are designed for installation through panels or walls. They provide a sealed connection on both sides, and one or both ends can swivel.

↪ Banjo Fittings: Feature a hollow bolt with a hose connection perpendicular to the bolt axis. They are often used in automotive and hydraulic applications.

↪ Hydraulic Couplings: Provide quick-connect and disconnect functionality for hydraulic systems, often with swivelling ends for flexibility.

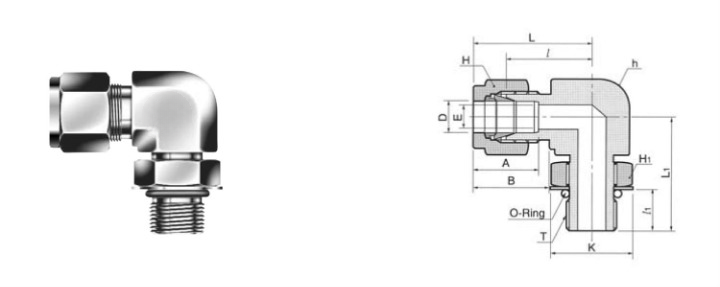

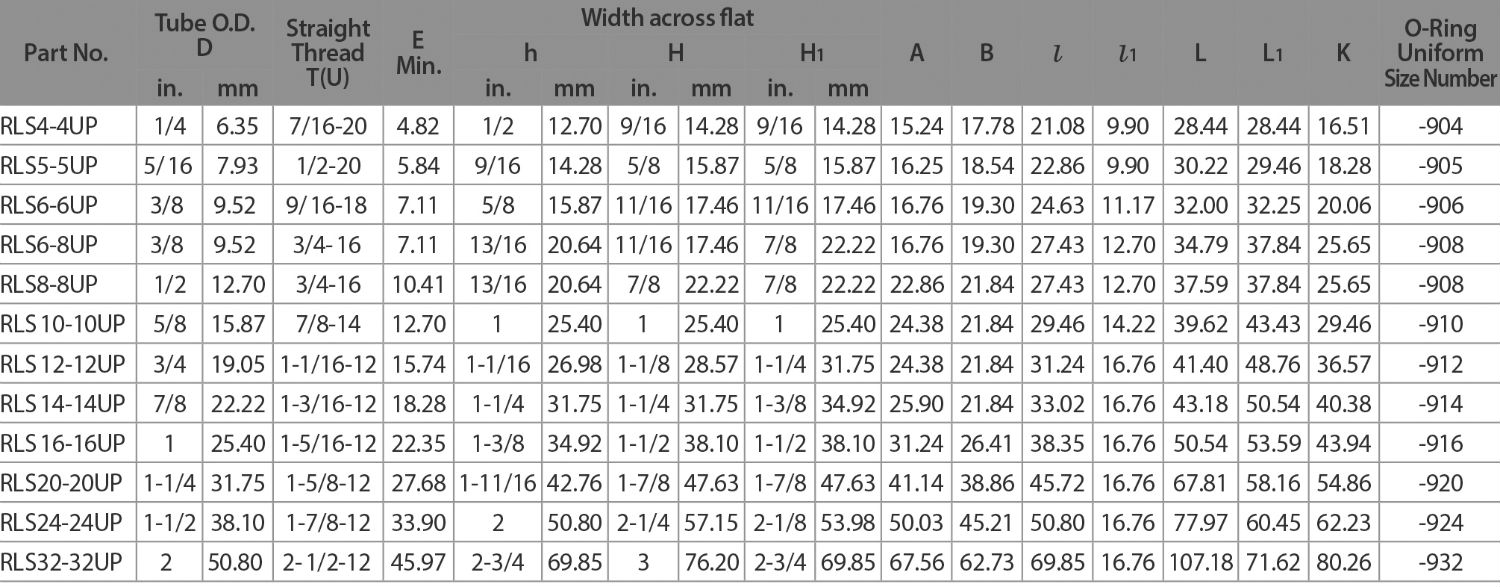

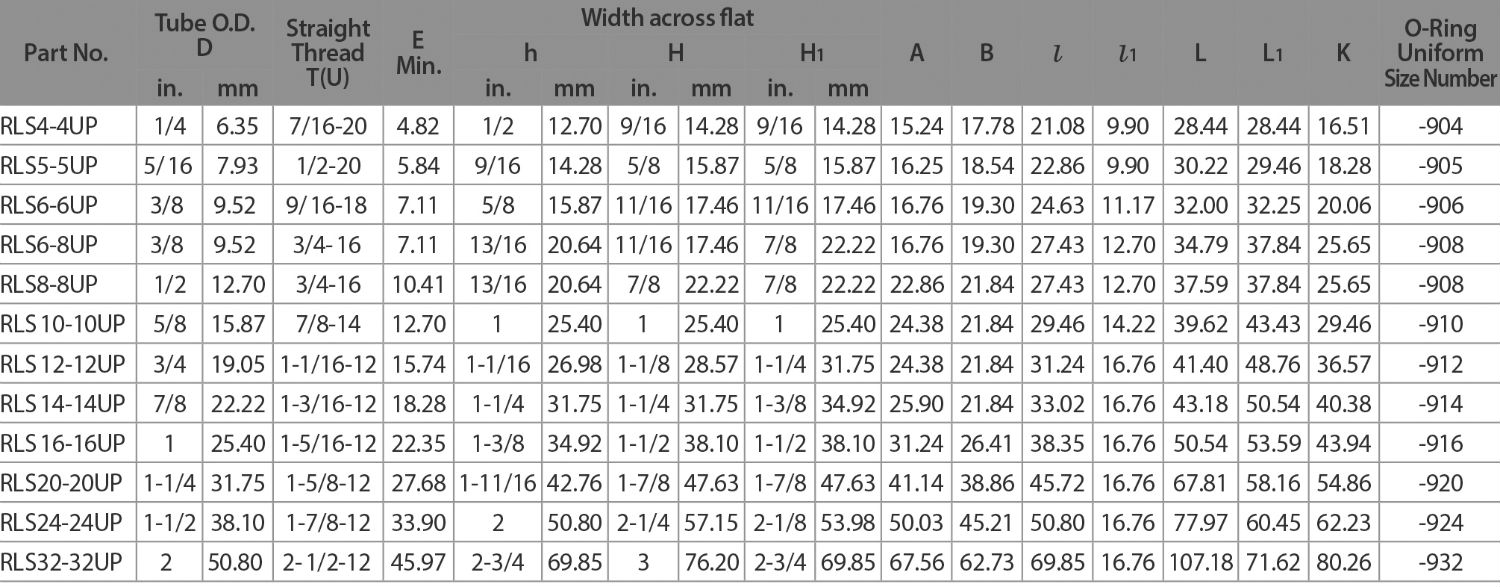

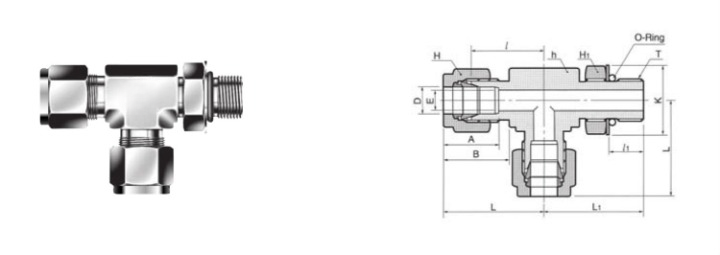

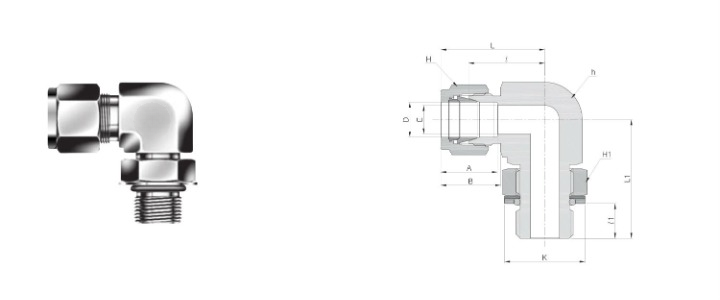

Positionable SAE Male Elbow RLS-UP

Join a fractional tube with an SAE Straight thread boss

Installation Instructions

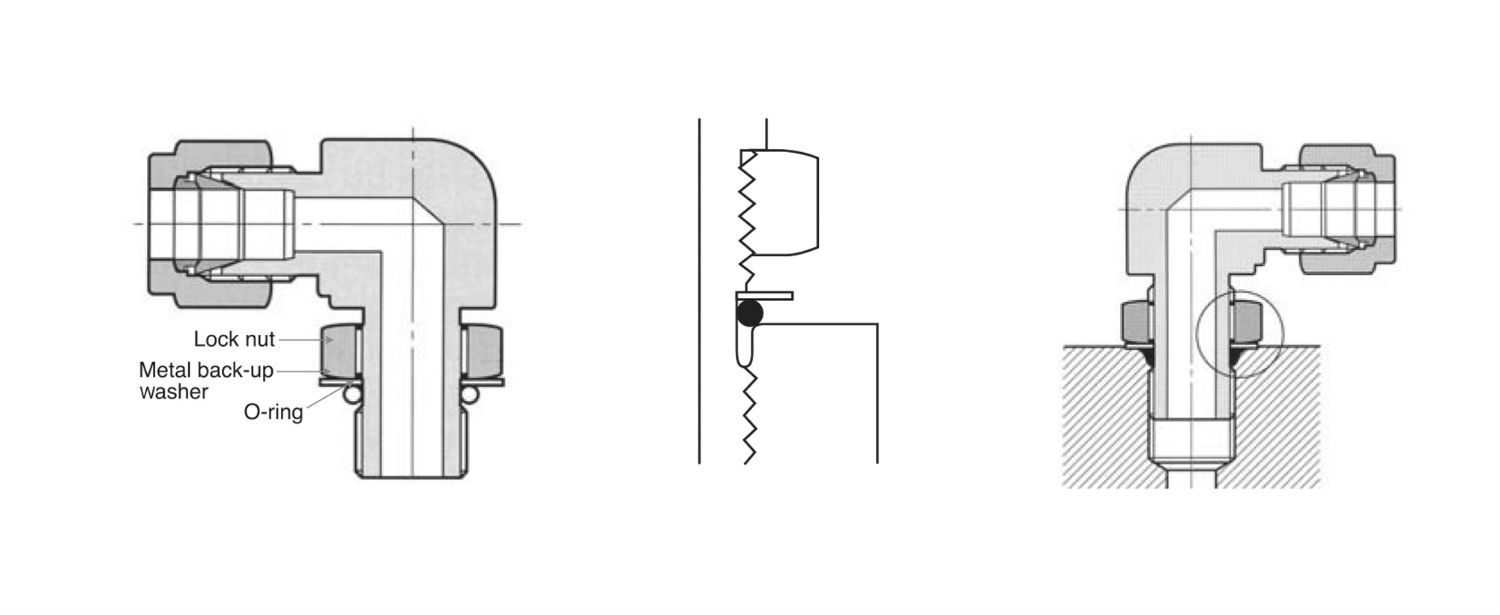

SAE and ISO parallel thread fittings

➢ Sealing: Proper sealing is essential to prevent leaks in the fluid or pneumatic system. Depending on the application and the type of fitting used, sealing may be achieved through the use of O-rings, gaskets, thread sealant, or other sealing methods.

➢ Installation: Positionable straight thread fittings are installed by screwing the threaded end into a compatible port or component using a suitable wrench or tool. The articulated joint allows for flexibility and adjustment as needed during installation or operation.

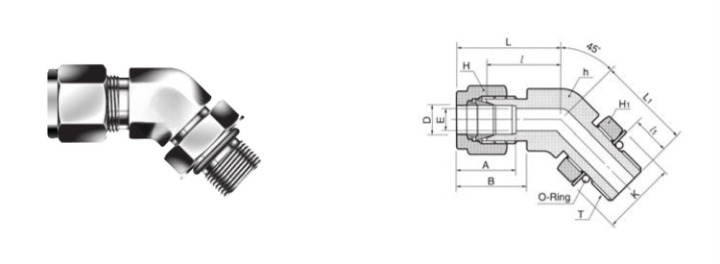

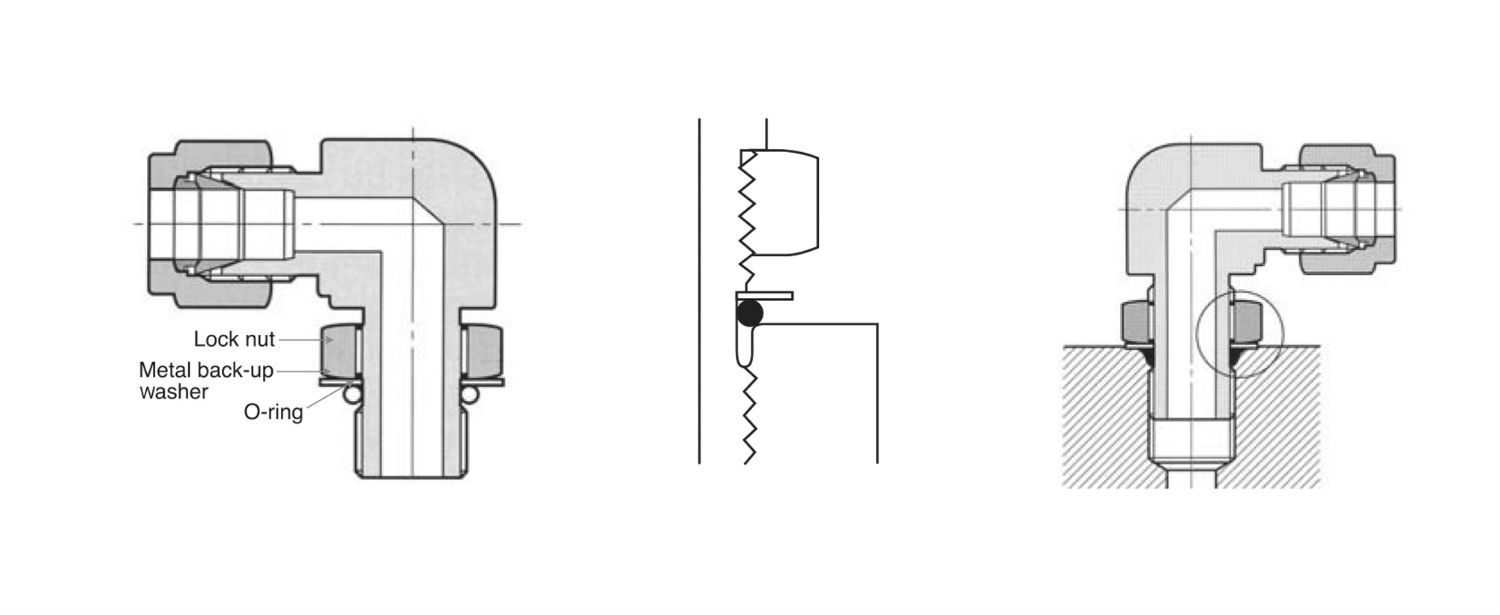

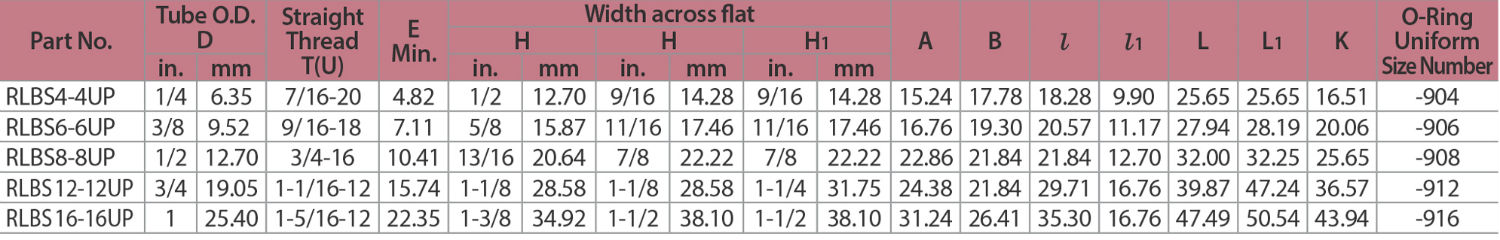

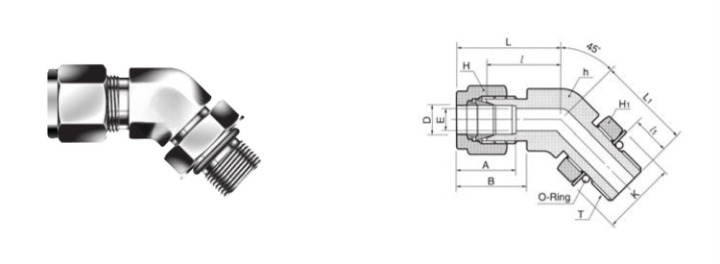

Positionable 45° SAE Male Elbow RLBS-U

Attach a fractional tube to an SAE straight thread boss

➢ Variants: There are different types of positionable straight thread fittings available to suit specific needs. Some examples include swivel elbows, swivel tees, swivel adapters, articulated fittings, and adjustable angle fittings.

➢ Thread Types: Positionable straight thread fittings may use various thread standards, including NPT (National Pipe Thread), BSP (British Standard Pipe), metric threads, or other specialized thread types, depending on the application and region.

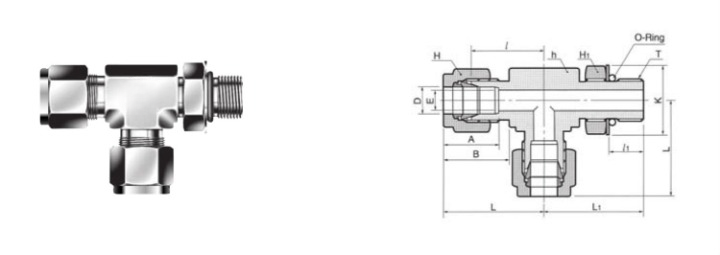

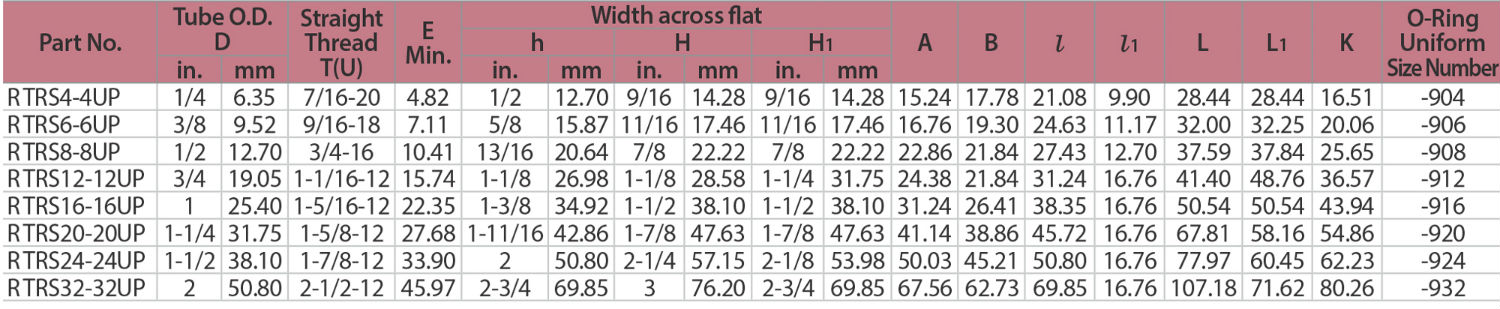

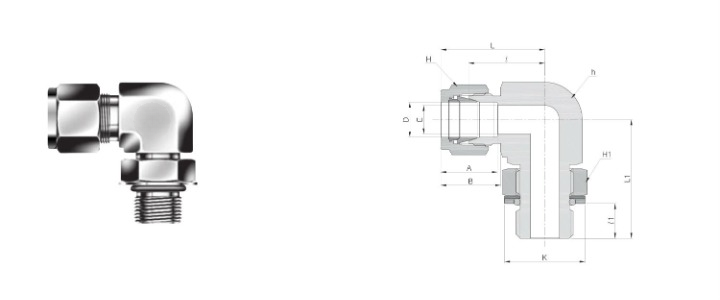

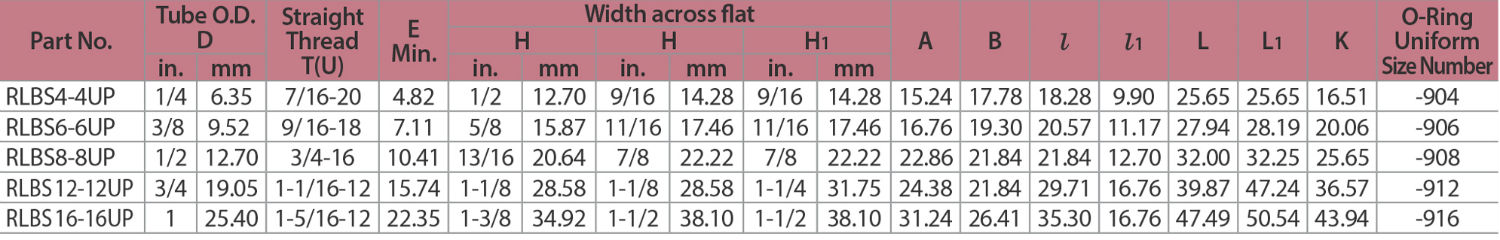

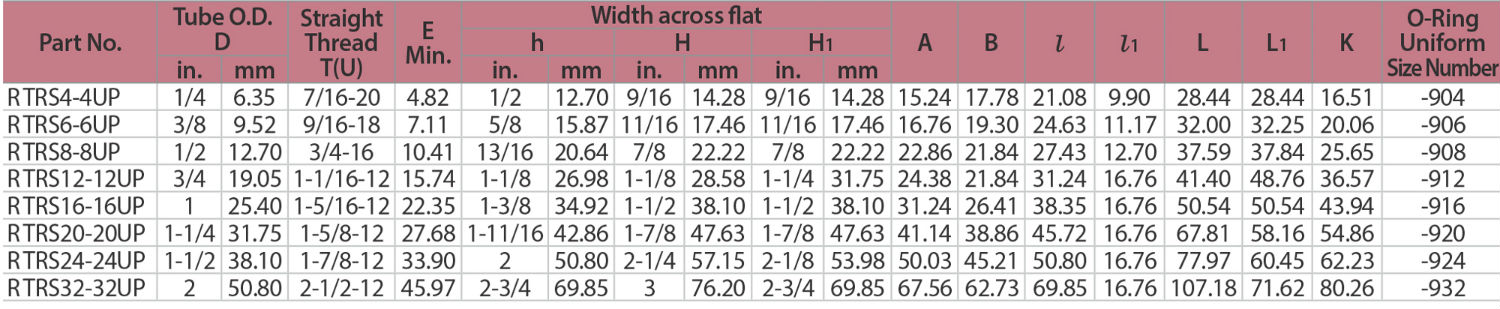

Positionable SAE Male Run Tee RTRS-UP

Joining a fractional tube to an SAE straight thread boss

➢ Maintenance: Regular inspection and maintenance of positionable straight thread fittings are necessary to ensure optimal performance and reliability. This includes checking for leaks, inspecting for wear or damage, and replacing any worn or damaged components as needed.

➢ Materials: These fittings are commonly made from brass, stainless steel, or various types of plastics, depending on the application requirements. The choice of material is based on factors such as compatibility with the fluid being conveyed, pressure, temperature, and environmental conditions.

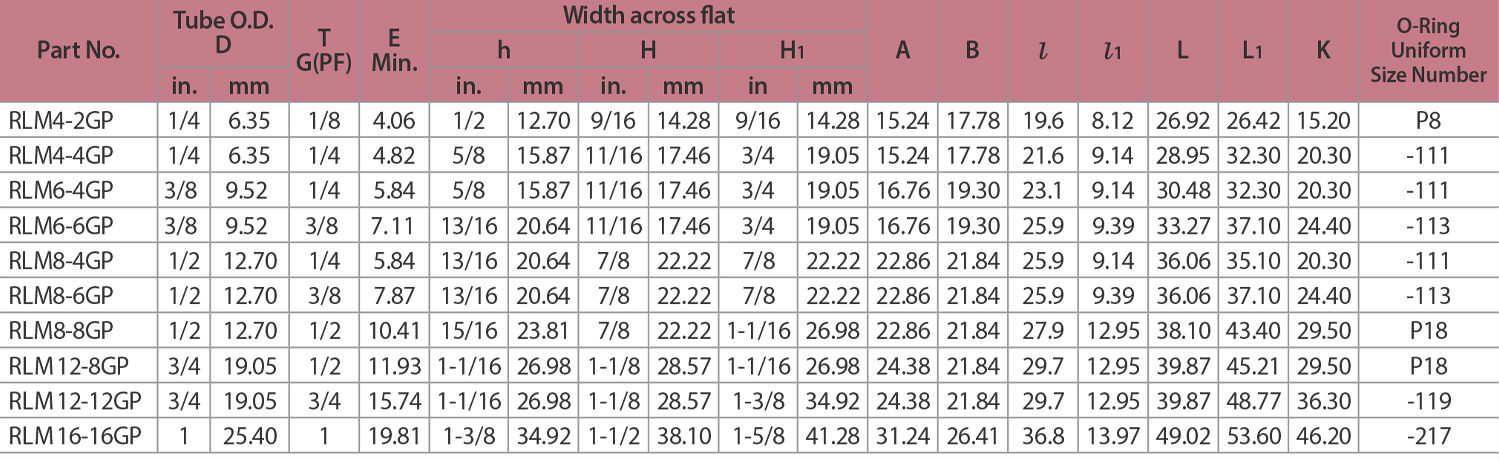

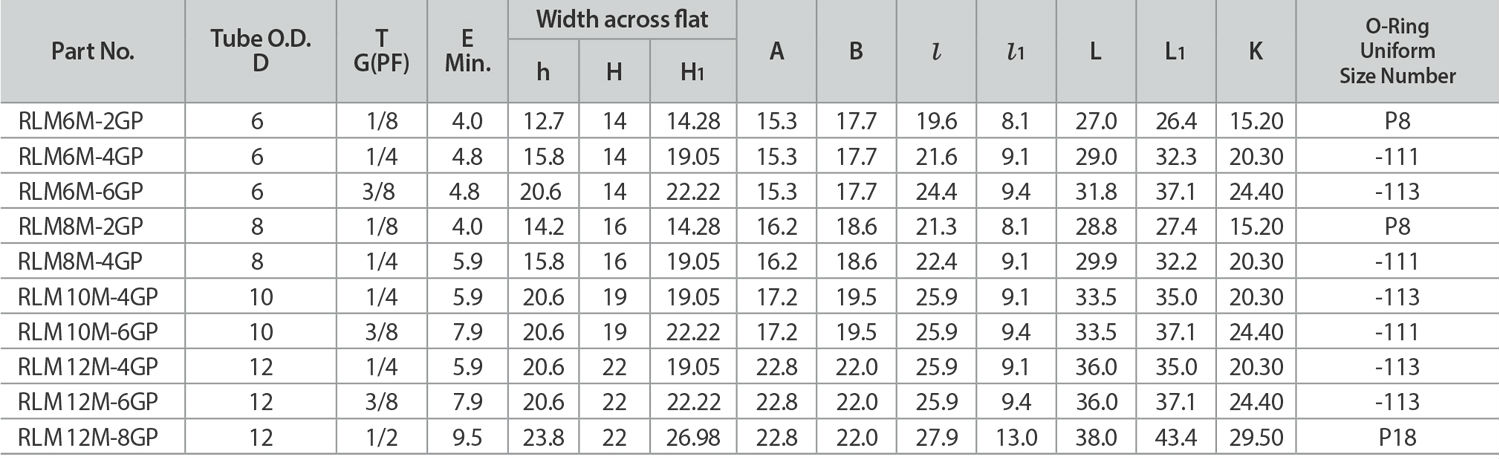

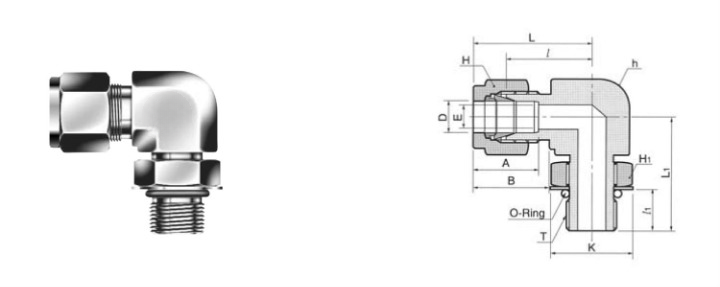

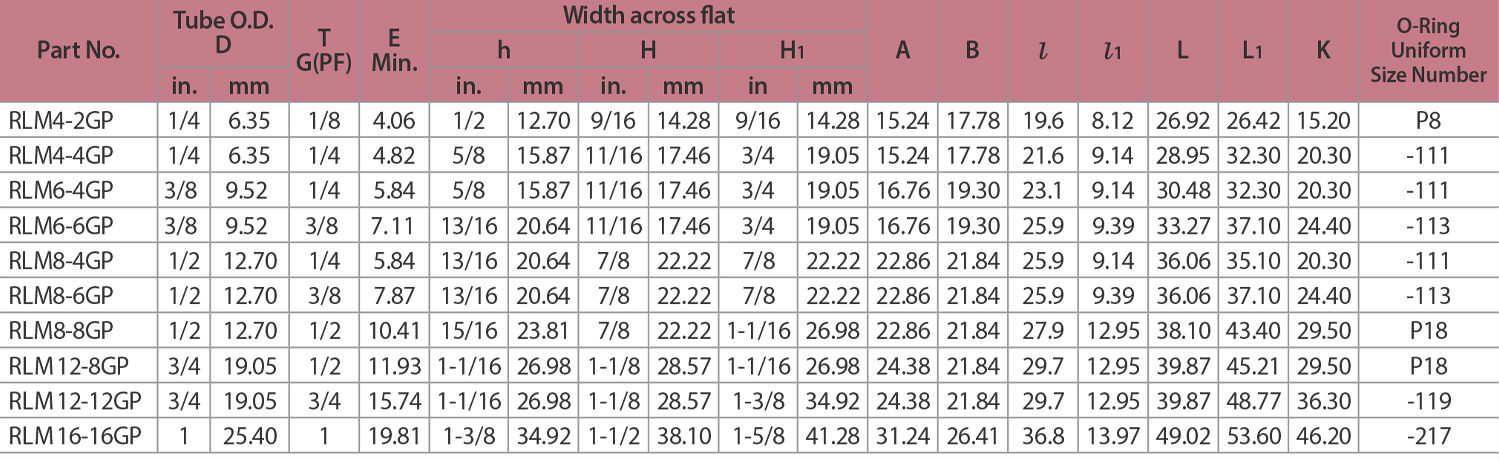

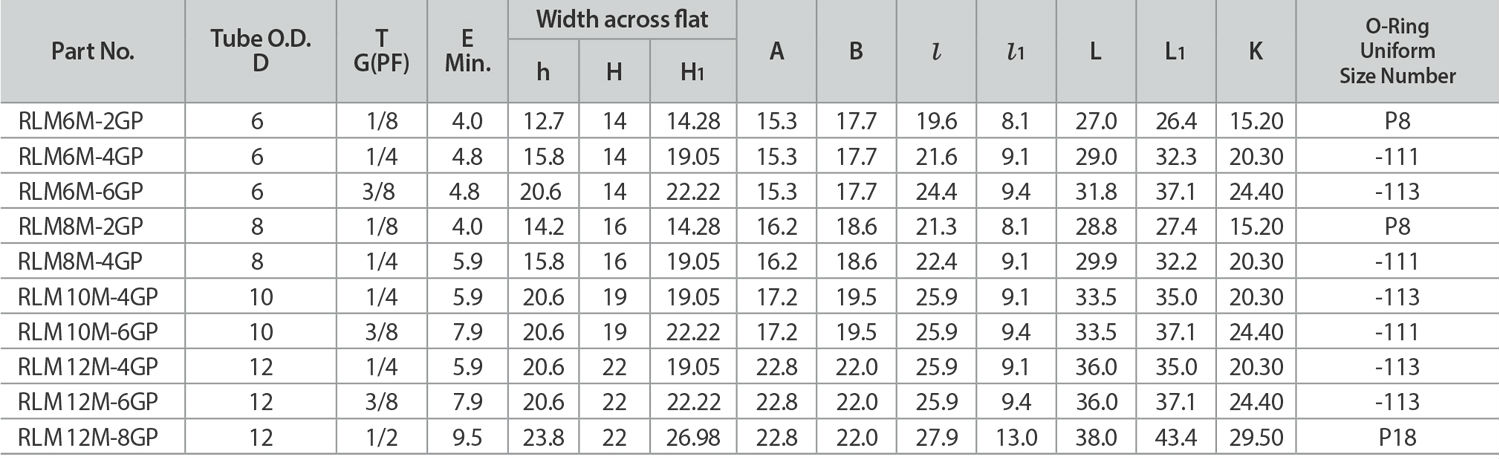

Positionable Male Elbow ISO Parallel thread RLM-GP

Connecting a fractional tube to an ISO parallel thread

Attaching a metric tube to an ISO parallel thread

➢ Design: Positionable straight thread fittings typically consist of a threaded end that attaches to a mating threaded port or component and a swivel or articulated joint that allows for movement or adjustment. The swivel joint may incorporate ball bearings or a similar mechanism to facilitate smooth rotation.

➢ Applications: These fittings are used in a wide range of industries and applications, including hydraulic systems, pneumatic systems, fluid transfer systems, industrial machinery, automotive systems, and more. They are beneficial in applications where precise alignment or adjustment of components is required.

All © Reserved by Renaissance Fittings and Piping Inc.( 2025 )