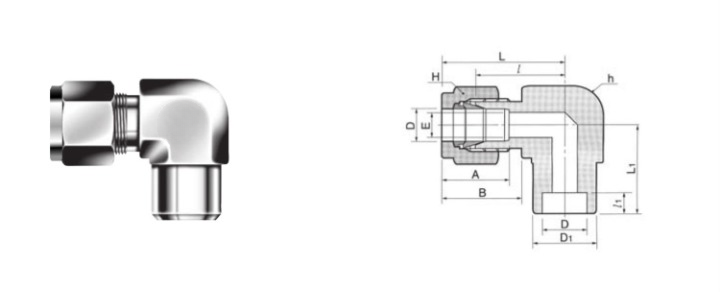

Tube Socket Weld Elbow RLSW

➯ The Tube Socket Weld Elbow (RLSW) is an essential component for directing flow in tubing systems while accommodating space constraints and maintaining system integrity.

➯ Whether used in chemical processing plants, power generation facilities, or industrial machinery, the RLSW elbow provides dependable fluid control and enhances system efficiency.

➯ This elbow is engineered to withstand high-pressure conditions, varying temperatures, and corrosive environments, ensuring reliable performance even in demanding industrial applications.

➯ The tube socket weld elbow RLSW is an integral component of tube fitting systems. It is meticulously designed to facilitate directional changes and seamless connections between tubes or pipes through socket welding processes.

➯ Featuring socket weld ends for easy installation onto the tubing, this elbow fitting allows for precise positioning and alignment within pipelines. Its robust construction and high-quality materials ensure long-lasting performance, even in harsh operating conditions.

↪ Corrosion Resistance: To withstand harsh operating conditions and corrosive environments, the elbow may feature corrosion-resistant coatings or finishes. This protective layer enhances the elbow's durability and ensures consistent performance in challenging industrial environments.

↪ Precision Engineering: Each elbow undergoes precision engineering processes to achieve precise tolerances and smooth surface finishes. This meticulous craftsmanship ensures a tight fit and optimizes the overall efficiency of the tubing system, minimizing frictional losses and pressure drops.

↪ Socket Weld End: The Tube Socket Weld Elbow RLSW features a socket weld end, allowing for seamless integration with tubes or pipes through socket welding techniques. This design eliminates the need for additional fittings or adapters, simplifying installation and reducing potential leak points.

↪ Angled Configuration: Designed with a specific angle, typically 90 degrees or 45 degrees, the elbow facilitates directional changes in piping systems while maintaining optimal flow characteristics. This angled configuration enables efficient routing of fluids or gases, particularly in tight or confined spaces.

↪ Leak-Proof Sealing: Engineered with precision sealing mechanisms, such as O-rings or gaskets, the elbow ensures a reliable and leak-proof seal between the connector and mating components. It prevents fluid or gas leakage, safeguarding the integrity of the tubing system and minimizing the risk of contamination.

↪ Premium Construction: Manufactured from high-grade materials such as stainless steel, carbon steel, or specialized alloys, the Tube Socket Weld Elbow RLSW ensures exceptional strength and durability. Its robust construction guarantees longevity and resistance against wear, corrosion, and mechanical stresses, ensuring consistent performance over time.

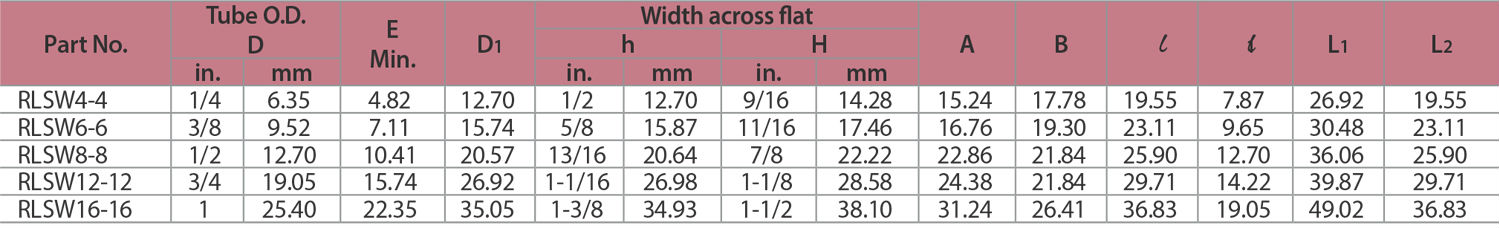

↪ Wide Range of Sizes and Configurations: The Tube Socket Weld Elbow RLSW is available in various sizes and configurations to accommodate different tube diameters, wall thicknesses, and application requirements. This versatility makes it suitable for use across diverse industries, including oil and gas, petrochemical, chemical processing, power generation, and more.

Connects fractional tubes

Applications

➢ Aerospace: Hydraulic and pneumatic systems.➢ Automotive: Fuel delivery systems, hydraulic circuits.

➢ Food and Beverage: Processing and packaging machinery.

➢ Pharmaceutical: Processing equipment, cleanroom environments.

➢ Oil and Gas: Pipeline systems, refineries, offshore platforms.

➢ Power Generation: Power plants, steam systems, cooling circuits.

➢ Petrochemical: Chemical processing plants and storage facilities.