Union

Union

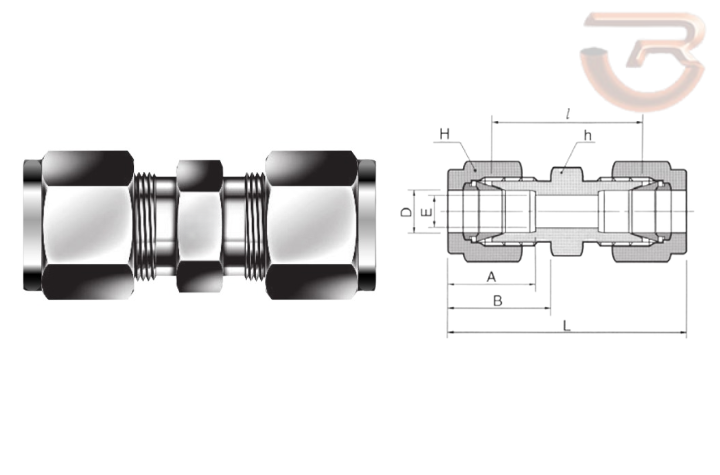

Union fittings are commonly used in piping and tubing systems to join two tubes or pipes, allowing for easy disassembly and reassembly. These fittings are handy in situations where maintenance or repairs may be necessary.

Components

Nut: The nut is a threaded component tightened onto the fitting to secure the union. It typically has internal threads that match the lines on the fitting.Body or Coupling: This is the central part of the union that connects the two tubes. It has external threads that match the nut and internal components that allow for a secure connection.

O-rings or Gasket: Many union fittings use O-rings or gaskets to provide a tight and leak-proof seal between the two tubes. When dealing with fluid-carrying systems, it is crucial to consider certain factors to ensure optimal performance and safety.

Ends: Union fittings can have various end connections, such as compression ends, flare ends, or other types, depending on the specific application.

Types

Compression Union: Commonly used in instrumentation and hydraulic systems, compression unions involve compressing a ferrule or ring onto the tubing to create a seal.Flare Union: In flare unions, the end of the tubing is flared outward, and a nut is used to secure the connection. This type is common in refrigeration and gas systems.

Threaded Union: These unions have threads on the nut and the body, allowing for easy assembly by twisting the two components together. They are common in plumbing applications.

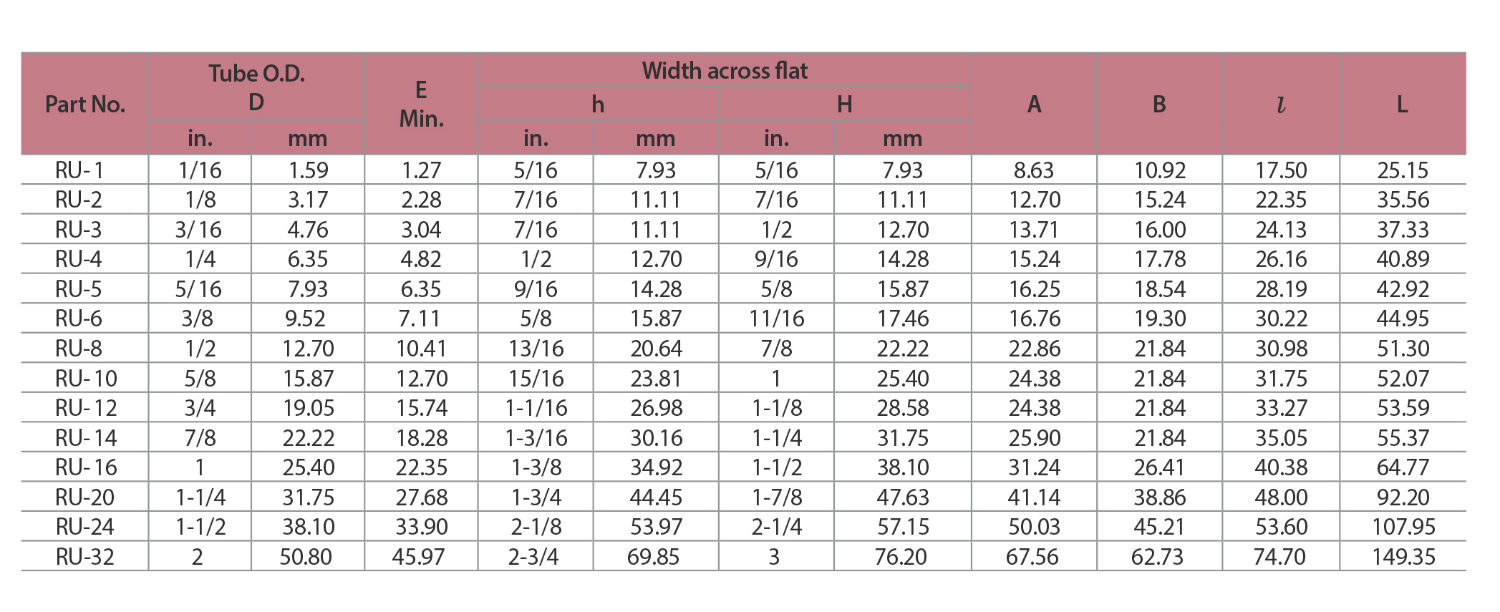

Connects Fractional Tube

Installation

Cutting and Flaring: Using a flare union, you must cut the tubing and flare the end to ensure a proper connection.Assembling: Slide the nut over the tubing, insert the tubing into the body of the union, and thread the nut onto the body. Tighten the nut to create a secure connection.

Tightening: Use the appropriate tools to tighten the nut securely. Be careful not to overtighten, as this can damage the components or cause leaks.

Considerations

Material Compatibility: Ensure that the materials of the union fittings are compatible with the substances flowing through the tubing.Application: Choose the type of union fitting based on the specific requirements of your application, considering factors like pressure, temperature, and the nature of the fluid or gas.

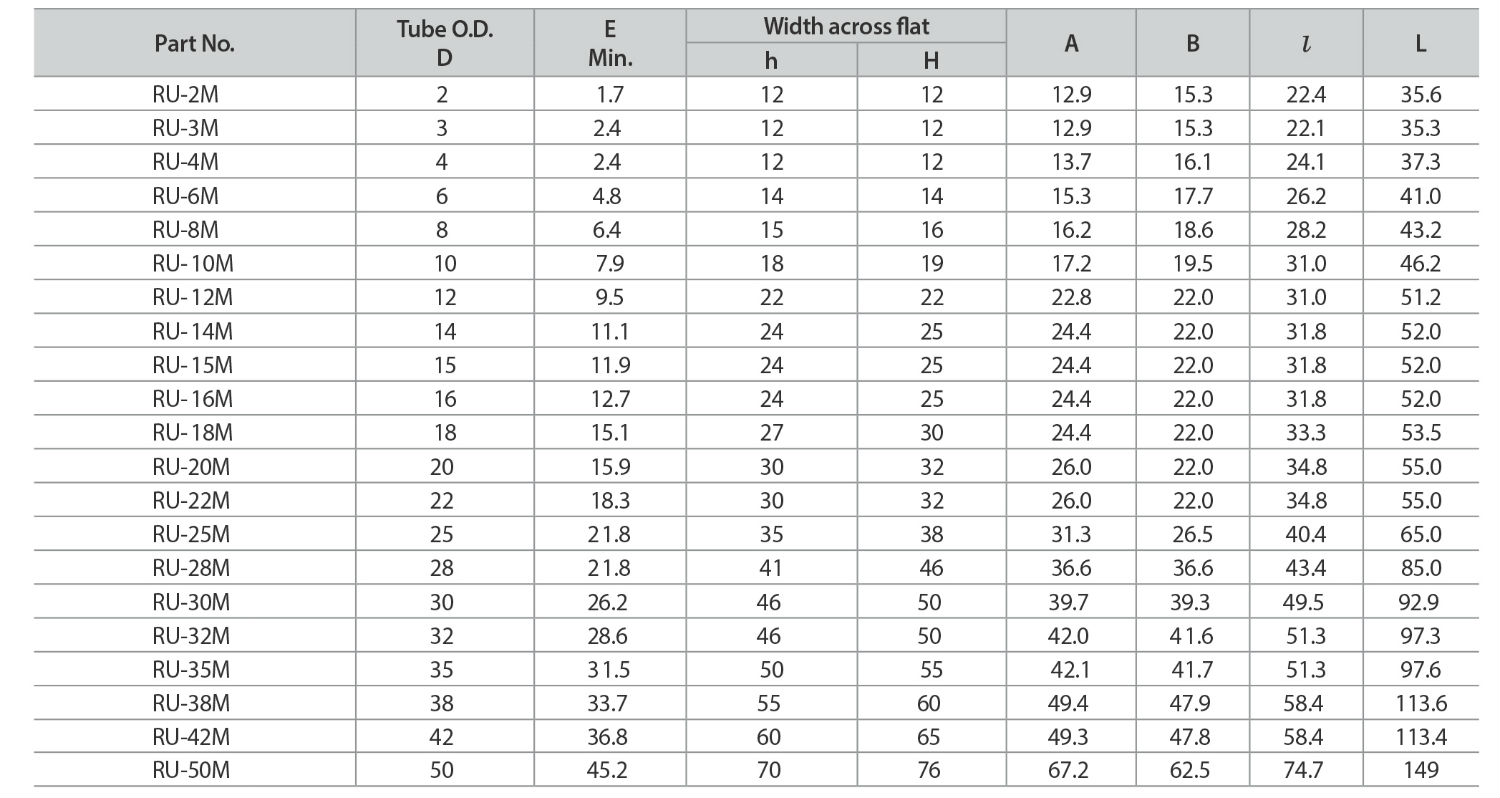

Connects Metric Tube

Note 👍 Always follow the manufacturer's guidelines and specifications for your specific union fitting to ensure a safe and reliable connection.