Lap Joint Flange Connector RLJ

Lap Joint Flange Connector RLJ

↪ Lap Joint Flanges, also known as Loose Flanges or Van Stone Flanges, consist of two separate.↪ The two main components required for a lap joint flange assembly are the stub end and the backing flanges.

↪ RLJ (Ring Type Joint) is a type of joint used in lap joint flanges. It provides a mechanism for aligning and securing the joint.

↪ Lap joint flanges are used in applications that require easy alignment and disassembly, such as low-pressure systems or systems requiring frequent maintenance.

↪ A Lap Joint Flange Connector with a Ring Type Joint (RLJ) is a specialized type of flange assembly used in piping systems where flexibility and ease of assembly and disassembly are required, along with enhanced sealing performance.

Lap Joint Flange (LJF)

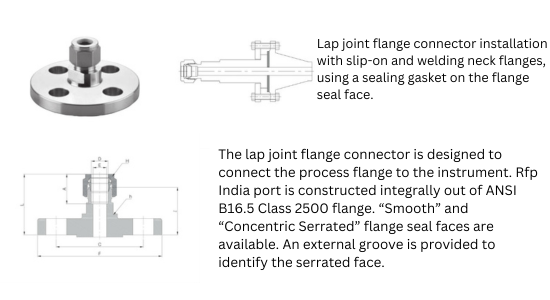

➢ Components: The lap joint flange consists of two main parts: the stub end and the backing flange.➢ Stub End: The stub end is welded to the pipe and features a narrow shoulder or extension where the backing flange slides over. It does not come into direct contact with the conveyed fluid.

➢ Backing Flange: The backing flange is the part that makes contact with the gasket and the mating flange during assembly. It has a flat face and is free to rotate around the stub end, simplifying alignment during installation and allowing for easy disassembly.

Ring Type Joint (RLJ)

➢ Sealing Mechanism: The RLJ is a type of sealing mechanism used in some lap joint flanges to ensure a tight and leak-proof seal.➢ Material: RLJs are typically made of metal, such as stainless steel, and are designed to sit in a specially machined groove on the face of the lap joint flange.

➢ Function: When the lap joint flange is assembled with the mating flange, the RLJ is compressed between the flange faces, forming a metal-to-metal seal that effectively prevents leakage, particularly in high-pressure and high-temperature applications.

Assembly and Disassembly

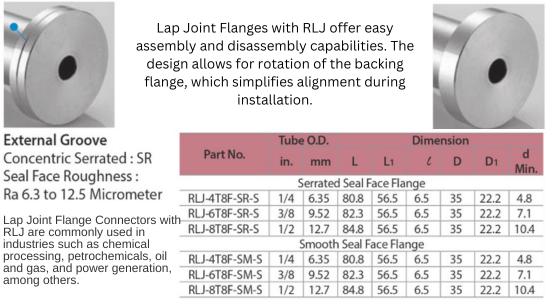

➢ Lap Joint Flanges with RLJ offer easy assembly and disassembly capabilities. The design allows for rotation of the backing flange, which simplifies alignment during installation.➢ This feature is especially advantageous in systems that require frequent maintenance or modification, as it allows for quick and convenient access to the piping system without the need for cutting or welding.

Applications

➢ Lap Joint Flange Connectors with RLJ are commonly used in industries such as chemical processing, petrochemicals, oil and gas, and power generation, among others.➢ They are suitable for applications where flexibility, ease of maintenance, and reliable sealing performance are essential, particularly in systems that handle corrosive or hazardous fluids or where operational conditions may vary.

Facilitates seamless connections between flanges and fractional tubes.

➢ DN50 (2-inch): HVAC systems in residential and commercial buildings, water distribution networks

➢ DN80 (3-inch): Chemical processing plants, industrial water treatment systems

➢ DN100 (4 inch): Oil refineries, power generation plants (steam or water lines)

➢ DN150 (6-inch): Wastewater treatment plants, food processing facilities

➢ DN200 (8-inch): Petrochemical plants (pipes carrying petroleum products), industrial cooling systems

➢ DN250 (10 inches): Offshore oil and gas platforms (subsea pipelines), mining operations (slurry transport)

➢ DN300 (12 inches): Natural gas distribution networks (transmission pipelines), chemical manufacturing plants

➢ DN350 (14 inches): Large-scale industrial facilities (main supply lines), wastewater management systems

➢ DN400 (16-inch): District heating systems (large-diameter pipes supplying heat), water desalination plants

➢ DN450 (18 inches): Main supply lines in industrial complexes, wastewater treatment plants

↪ DN50 (2 inch) ✦ DN80 (3 inch) ✦ DN100 (4 inch) ✦ DN150 (6 inch) ✦ DN200 (8 inch) ✦ DN250 (10 inch) ✦ DN300 (12 inch) ✦ DN350 (14 inch) ✦ DN400 (16 inch) ✦ DN450 (18 inch) ✦ N500 (20 inch) ✦ DN600 (24 inch) ✦ DN700 (28 inch) ✦ DN800 (32 inch) ✦ DN900 (36 inch) ✦ DN1000 (40 inch) ✦ DN1200 (48 inch) ✦ DN1400 (56 inch) ✦ DN1600 (64 inch) ✦ DN1800 (72 inch)