Ferrule Set

Ferrule Set:

↪ A ferrule set in spare parts typically refers to a collection of ferrules used in various fittings, particularly in fluid or gas systems.↪ A ferrule set refers to a collection of ferrules. Ferrules are small, typically cylindrical components often made of metal or plastic that are used in conjunction with nuts in compression fittings. They are designed to provide a seal and grip on the outside of the tubing or pipe when compressed by the nut.

Types

➢ Front Ferrule: Also known as a sealing ferrule or compression ring, the front ferrule is positioned closest to the fitting nut in a compression fitting assembly. It is responsible for creating a seal between the fitting body and the tubing when compressed against the fitting body by the nut.➢ Back Ferrule: The back ferrule, also known as the anchoring or gripping ferrule, is positioned behind the front ferrule in a compression fitting assembly. Its primary function is to grip and support the tubing when compressed against the front ferrule by the fitting nut, ensuring a secure connection.

➢ Single Ferrule vs. Double Ferrule: Compression fittings may use either a single ferrule (e.g., a front ferrule only) or a double ferrule design (e.g., both front and back ferrule). Double ferrule designs offer improved sealing and grip, making them more common in high-pressure or critical applications.

➢ Material: Ferrules are typically made of materials such as brass, stainless steel, carbon steel, or plastics like PTFE (polytetrafluoroethylene). The choice of material depends on factors such as compatibility with the fluid or gas being conveyed, temperature, pressure, and corrosion resistance requirements.

Applications

↪ Ferrules are used in a wide range of industries and applications, including plumbing, hydraulic systems, pneumatic systems, instrumentation, automotive, and process industries.↪ They are particularly well-suited for applications requiring leak-tight connections, such as those involving corrosive fluids, high pressures, or high temperatures.

↪ Ferrules are commonly used in compression fittings, where they offer advantages such as ease of assembly, reusability, and resistance to vibration and thermal cycling.

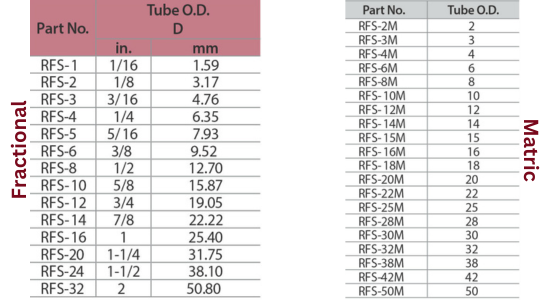

Fitting Sizes & Tube Outer Diameter (OD):

↪ Metric sizes are also prevalent, such as: 4mm, 6mm, 8mm, 10mm, 12mm, 15mm, 18mm, 22mm, 28mm, etc.↪ Ferrules outer diameter of the tubing they are intended to seal. 1/8", 3/16", 1/4", 5/16", 3/8", 1/2", 5/8", 3/4", 1", etc.

Fractional and Matric

Spare Parts and Maintenance

↪ Proper selection of ferrule sets based on size, material, and application requirements is crucial to ensuring the reliability and integrity of fluid or gas systems.↪ Ferrule sets are essential spare parts commonly stocked by manufacturers, distributors, and maintenance departments to ensure the availability of replacement components for repair and maintenance activities.

↪ Ferrules are made from various materials, including brass, stainless steel, carbon steel, and plastics like PTFE (polytetrafluoroethylene). The choice of material depends on factors such as compatibility with the fluid being conveyed, temperature, pressure, and corrosion resistance requirements.

Function

↪ Ferrules are small, typically cylindrical components made of metal or plastic. They are used in conjunction with fittings, nuts, and tubing to create leak-tight connections in fluid or gas systems.↪ The primary function of ferrules is to provide a seal and grip on the outside surface of the tubing or pipe when compressed by the fitting nut. This compression creates a secure, leak-resistant connection.

Industry Standards:

↪ The choice of ferrule size may also depend on specific application requirements, such as operating pressure, temperature range, fluid compatibility, and environmental conditions.↪ Depending on the industry and geographic location, specific standards may dictate the sizing and specifications of ferrules. For example, in the United States, standards from organizations like ASTM or SAE may apply, while in Europe, standards from organizations like DIN or ISO may be more prevalent.