Flanges

Flanges are essential components in various mechanical systems, particularly in piping systems, where they connect tubes, pipes, valves, pumps, and other equipment. They provide a means for easy assembly and disassembly of piping components while ensuring a secure and leak-proof connection.

Types of Flanges

➢

Weld Neck Flange: Features a long, tapered hub that provides an ideal connection for butt welding to pipes.

➢

Slip-On Flange: Designed to slide over the pipe and tube, then welded in place.

➢

Socket Weld Flange: Similar to slip-on flanges but with a socket for welding to the pipe.

➢

Threaded Flange: Used with pipes with external threads, allowing for easy installation and removal.

➢

Blind Flange: Used to seal the end of a pipe, valve, or pressure vessel, preventing flow.

➢

Lap Joint Flange: Consist of two parts a stub end and a backing flange facilitating easy alignment and assembly.

➢

Orifice Flange: Specifically designed for orifice metering applications, featuring a small orifice to measure flow rates.

➢

Expander Flange: Increase the pipe size gradually.

➢

Standards: Flanges are manufactured to various standards, including ANSI/ASME (American National Standards Institute/American Society of Mechanical Engineers), API (American Petroleum Institute), DIN (Deutsches Institut für Normung), and others, ensuring compatibility and interchangeability between components.

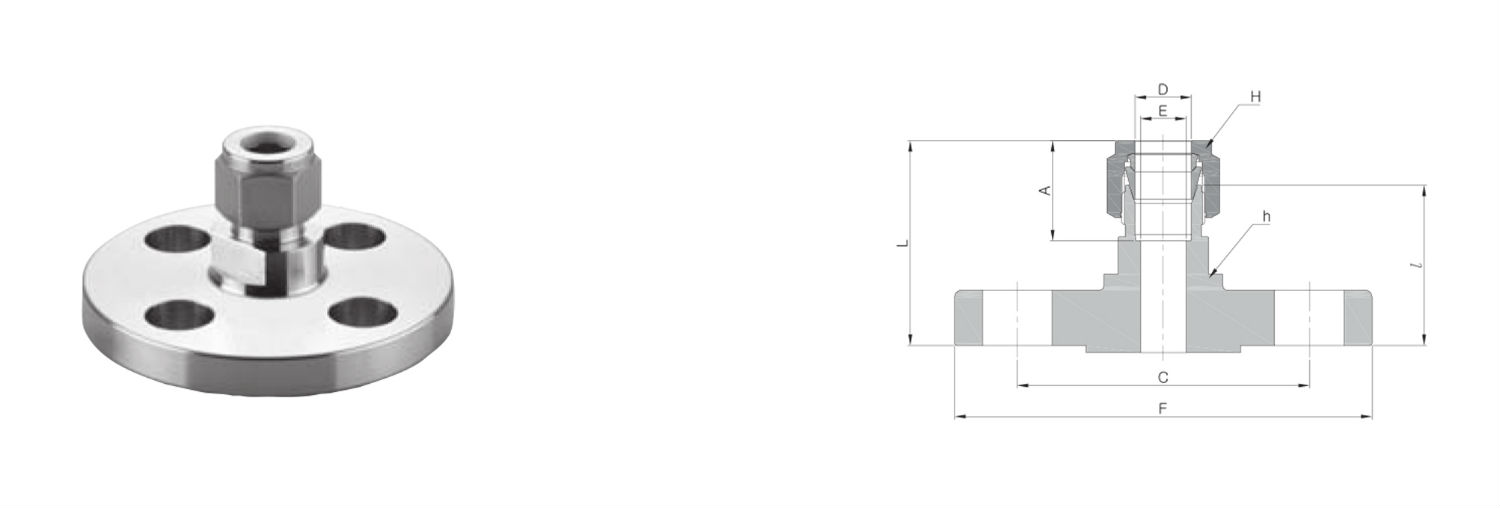

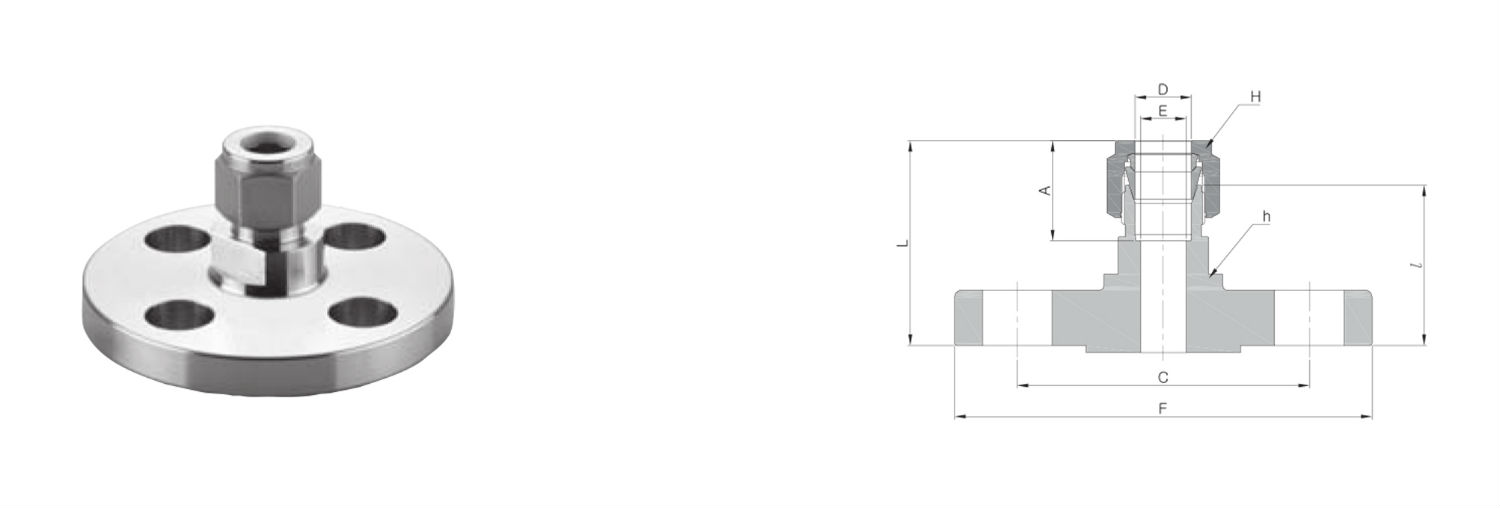

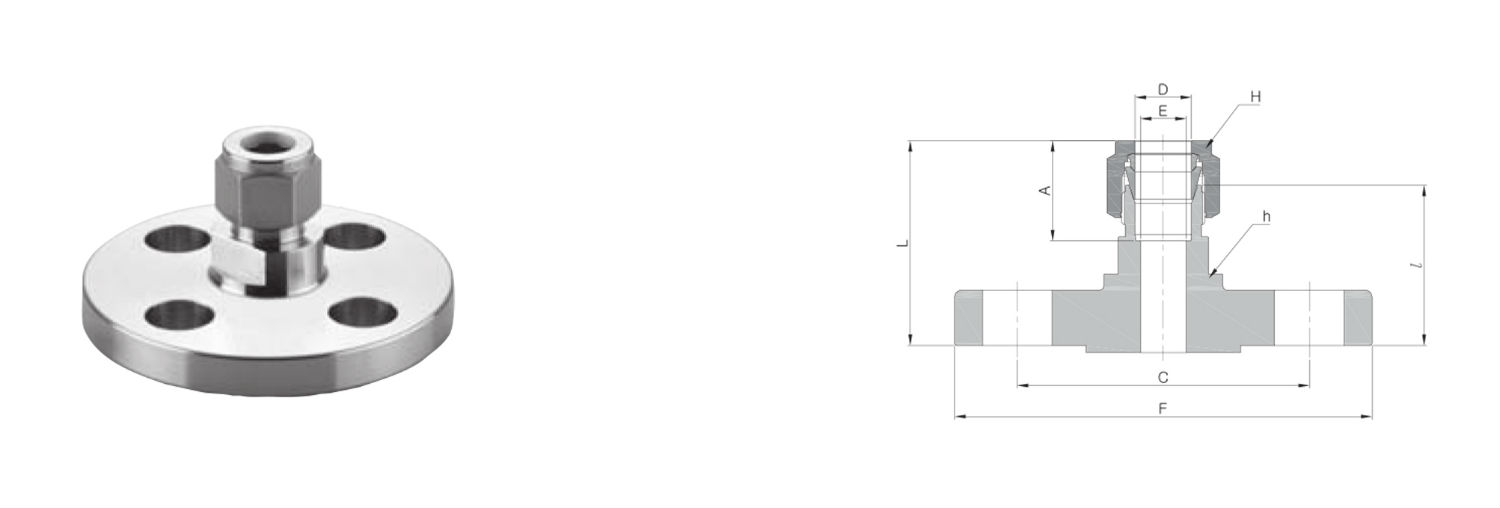

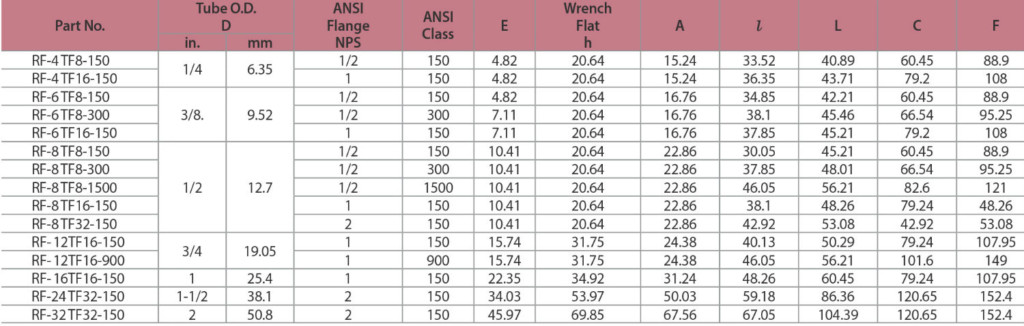

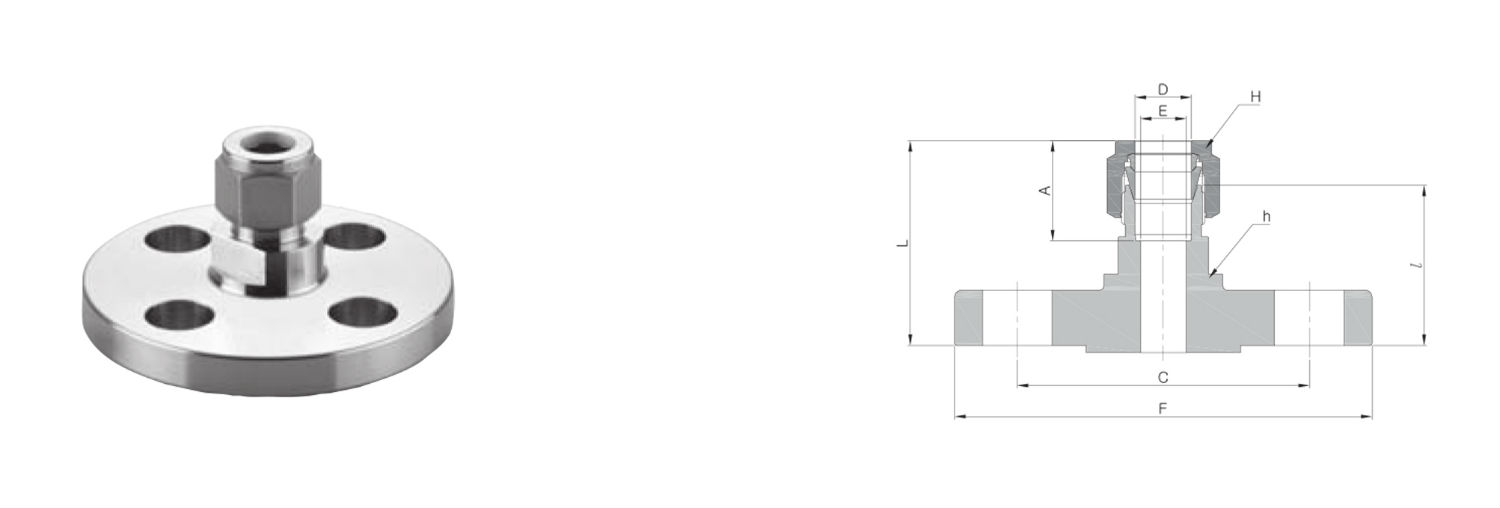

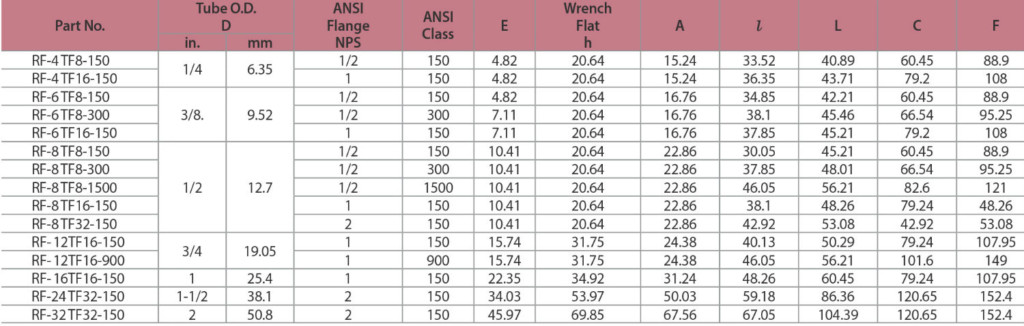

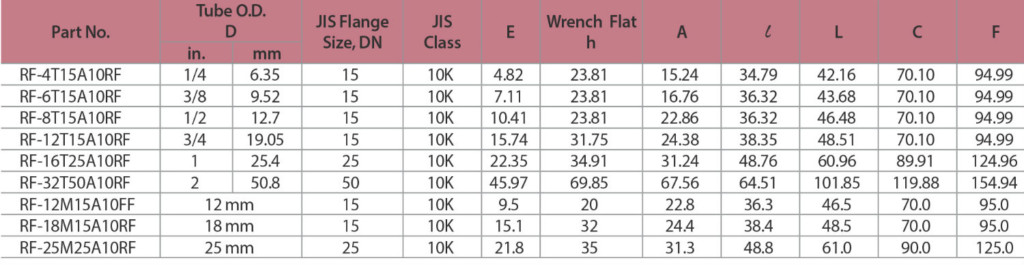

RFP Flanges ANSI B16.5 RF

ANSI B16.5 RF Flanges

↪ These flanges conform to the ANSI (American National Standards Institute) B16.5 standard.

↪RF (Raised Face) denotes the type of flange facing, which features a raised surface around the bolt holes to accommodate a gasket for a tight seal.

↪ANSI B16.5 RF flanges are widely used in industries following ANSI standards, such as oil and gas, chemical, and power generation.

Connect ANSI flanges to fractional tubes with pressure class ratings from 150 to 2500 for NPS 1/2 inch.

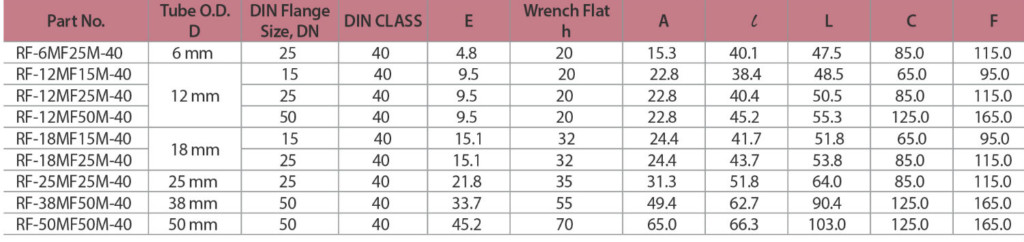

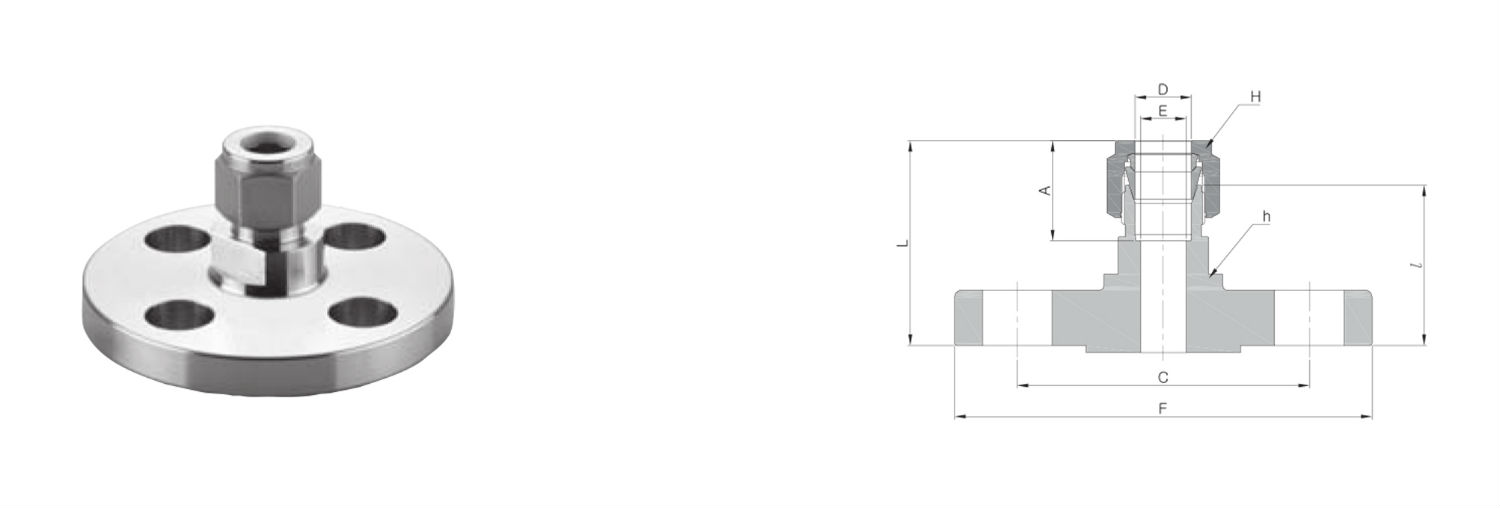

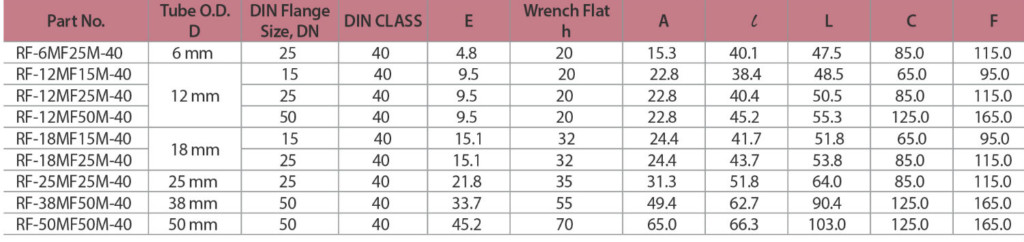

RFP DIN 2526/DIN 2501 RF Flanges

DIN 2526/DIN 2501 RF Flanges

↪ DIN 2526 and DIN 2501 are German standards established by DIN (Deutsches Institut für Normung).

↪ RF (Raised Face) indicates the facing type, similar to ANSI B16.5 RF flanges.

↪ These flanges adhere to DIN specifications and are commonly used in industries where DIN standards are prevalent, such as Europe and some parts of Asia.

Connect DIN flanges to metric tubes with pressure class ratings up to PN 320, covering nominal flange sizes from DN 15 to 50.

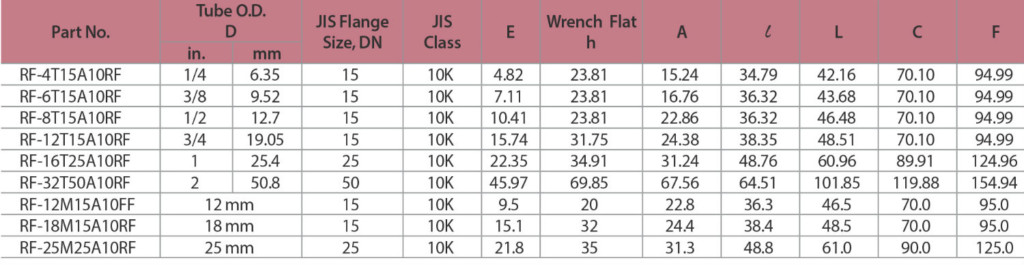

Easily connect JIS flanges to fractional or metric tubes with pressure class ratings ranging from 10 to 63k, suitable for nominal flange sizes from DN 15 to 50.

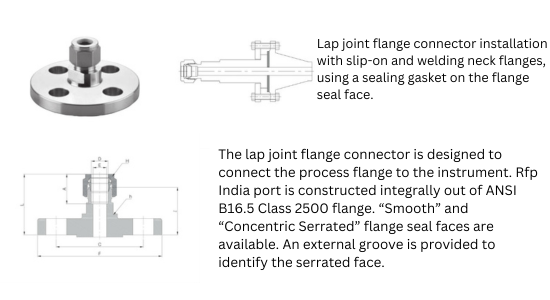

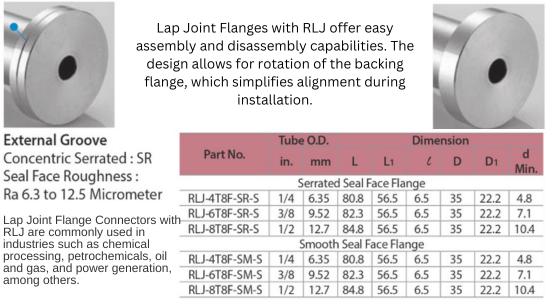

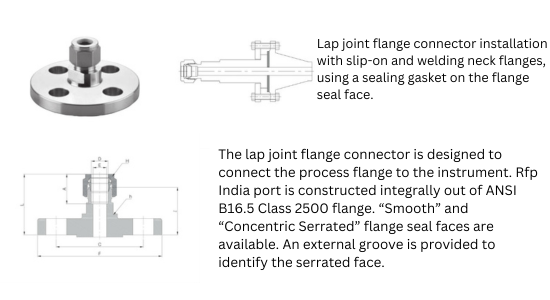

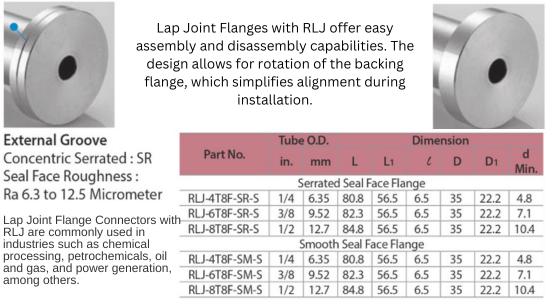

Lap Joint Flange Connector RLJ

Lap Joint Flange Connector RLJ

↪ Lap Joint Flanges, also known as Loose Flanges or Van Stone Flanges, consist of two separate.

↪ The two main components required for a lap joint flange assembly are the stub end and the backing flanges.

↪ RLJ (Ring Type Joint) is a type of joint used in lap joint flanges. It provides a mechanism for aligning and securing the joint.

↪ Lap joint flanges are used in applications that require easy alignment and disassembly, such as low-pressure systems or systems requiring frequent maintenance.

Facilitates seamless connections between flanges and fractional tubes.

➢

Type of Connection: Flanges can be welded, threaded, or screwed onto pipes, depending on the application requirements.

➢

Facing: Flange facing refers to the surface finish of the flanges that come in contact with the gasket. Standard meeting types include flat face (FF), raised face (RF), and ring-type joint (RTJ).

➢

Pressure Class: Flanges are rated according to pressure classes, indicating their ability to withstand pressure. Standard pressure classes include 150, 300, 600, 900, 1500, and 2500.

➢

Material: Flanges are available in various materials, including carbon steel, stainless steel, alloy steel, and other materials suitable for the intended application and environmental conditions.

↪ These flanges serve various purposes in piping systems, providing secure connections, facilitating assembly and disassembly, and ensuring leak-proof seals under pressure. Proper selection of flanges based on standards, facing type, pressure ratings, and application requirements is crucial for the integrity and efficiency of piping systems.

All © Reserved by Renaissance Fittings and Piping Inc.( )