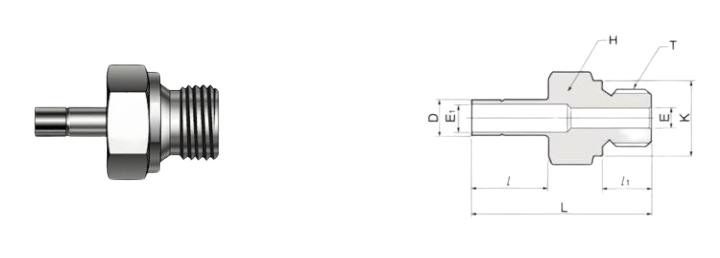

Male Adapter RAM-G

Male Adapter RAM-G

The Male Adapter (RAM-G) is a vital component in fluid handling systems, designed to establish a secure connection between male-threaded and female-threaded members. It enables efficient fluid or gas transfer while ensuring system integrity and reliability.

Applications

➢ Plumbing Systems: Utilized in residential, commercial, and industrial plumbing systems for connecting pipes, valves, and fixtures.➢ Fluid Handling Systems: Integral components in fluid handling applications such as pneumatic systems, hydraulic systems, pneumatic systems, and process piping.

➢ HVAC Systems: Deployed in heating, ventilation, and air conditioning (HVAC) systems for connecting pipes and components.

➢ Industrial Equipment: Essential in various industrial equipment and machinery requiring fluid or gas transfer.

➢ Automotive Industry: Employed in automotive systems for connecting fluid lines, including fuel lines, coolant lines, and hydraulic systems.

➢ Marine Applications: Best used in marine systems for fluid transfer within vessels and offshore installations.

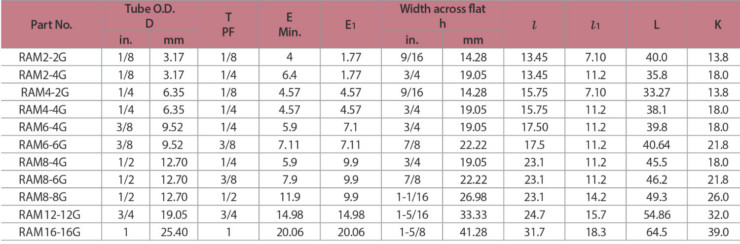

Connects fractional port to female ISO tapered thread

Key Features

➢ Male Threaded End: Features external threads on one end, specifically designed to mate with a female-threaded component such as a pipe, valve, or fitting.➢ Adapter Functionality: Acts as an intermediary interface between components with different thread types or sizes, providing versatility in system design and configuration.

➢ Robust Construction: Constructed from high-quality materials such as stainless steel, brass, or PVC, ensuring durability, corrosion resistance, and longevity in various operating environments.

➢ Precision Engineering: Engineered with precision tolerances to ensure a tight and reliable fit, minimizing the risk of leaks or system failures.

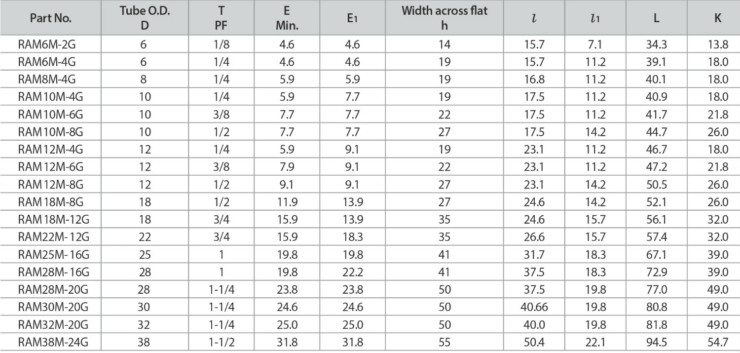

➢ Variety of Sizes: Available in various sizes and thread configurations to accommodate diverse system requirements and specifications.

➢ Sealing Mechanism: Incorporates effective sealing mechanisms such as O-rings or gaskets to establish a leak-tight connection, maintaining system integrity.

➢ Easy Installation: Designed for straightforward installation, reducing installation time and labour costs during system setup or maintenance procedures.

Obtaining Specifics

➢ Manufacturer's Documentation: Refer to the manufacturer's product specifications, datasheets, and installation guides for detailed information on sizing, materials, pressure ratings, and installation procedures.➢ Supplier Catalogs: Explore supplier catalogues specializing in fluid system components for comprehensive details on Male Adapter options and compatibility with specific systems.

➢ Consultation: Seek guidance from industry experts, engineers, or suppliers to ensure the selection of the appropriate Male Adapter based on specific system requirements and environmental considerations.

Connects metric port to female ISO tapered thread

Benefits

➢ Reliable Connection: Provides a secure and leak-free connection between male-threaded and female-threaded components, ensuring dependable fluid transfer.➢ Versatility: Compatible with various fluid types and system configurations, offering flexibility in system design and implementation.

➢ Durability: Construct from robust materials, ensuring long-term performance and resistance to corrosion and wear.

➢ Ease of Installation: Designed for straightforward installation, reducing downtime and labour costs during system setup or maintenance activities.

➢ Minimal Maintenance: Minimizes the risk of leaks and system failures, reducing maintenance requirements and enhancing system reliability.

➢ Cost-Effectiveness: Offers cost-effective solutions for fluid system connections, contributing to overall system efficiency and performance.

↪ The Male Adapter (RAM-G) is an essential component in fluid handling systems, providing a reliable and efficient connection between male-threaded and female-threaded members. By selecting the appropriate Male Adapter and following recommended installation practices, system integrity and performance can be maintained, ensuring the seamless operation of fluid transfer applications.