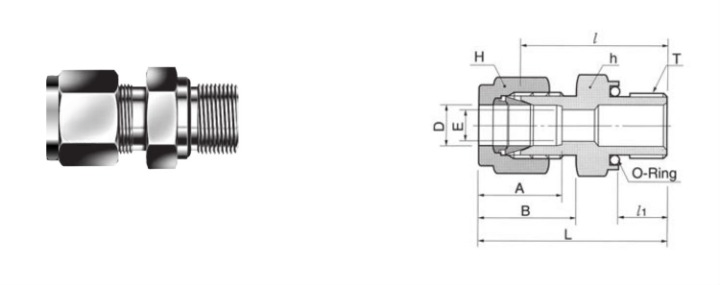

Non-Positionable O-SEAL

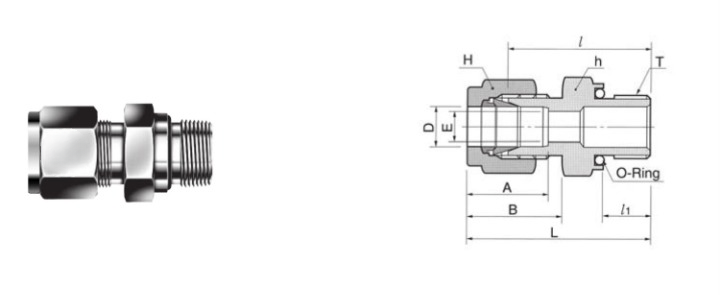

Non-Positionable O-SEAL

↪ Tube connection to a non-positionable O-seal connection involves several steps and considerations.↪ The process typically requires replacing the tube fitting with a fitting compatible with an O-seal design.

↪ Identify Components: Understand the current tube connection setup, including the size and type of fittings involved.

↪ Prepare the System: Shut off any valves and depressurize the system if necessary. Ensure safety precautions are followed.

↪ Document Changes: Update any relevant documentation or schematics to reflect the system's changes for future reference.

↪ Prepare O-Seal Fitting: Apply any necessary sealant or thread tape to the threads of the new O-seal fitting to ensure a tight seal.

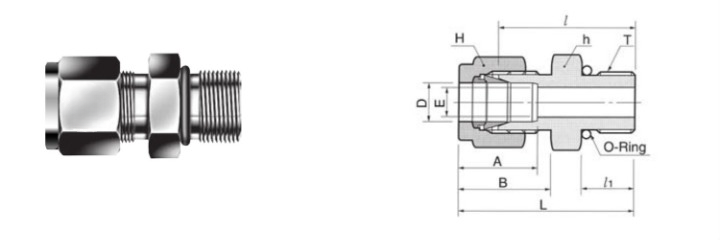

↪ Test System: Conduct thorough testing to ensure the system operates as expected with the new non-positionable O-seal connection.

↪ Remove Existing Tube Fitting: Disconnect the tube from the existing fitting using appropriate tools. Be careful to avoid damaging other components.

↪ Install O-Seal Fitting: Screw the O-seal fitting into the exact location where the tube fitting was removed. Tighten it securely using the appropriate tools.

↪ Secure and Label: Once everything is functioning correctly, secure any loose components and label the new connection appropriately for future reference.

↪ Attach Tubing: Once the fitting is securely in place, reattach the tubing to the new O-seal fitting. Ensure it is properly aligned and tightened to prevent leaks.

↪ Maintenance and Monitoring: Regularly monitor the new connection for any signs of wear or leaks and perform routine maintenance as needed to ensure continued reliability.

↪ Check for Leaks: Pressurize the system and check for any leaks around the new fitting. If leaks are present, tighten connections as needed and retest until no leaks are detected.

↪ Select Replacement Fitting: Choose a fitting compatible with O-seals. This fitting should have the same thread type and size as the existing tube fitting but designed for O-seal compatibility.