Back Ferrule

Back Ferrule

↪ The back ferrule is a critical component in compression fittings used to create secure and leak-tight connections in tubing systems.↪ The back ferrule, also known as the anchoring or gripping ferrule, is positioned behind the front ferrule in a compression fitting assembly.

↪ Its primary function is to grip and support the tubing when compressed against the front ferrule by the fitting nut, ensuring a secure connection.

Application Specifics

↪ They are particularly suitable for applications involving high pressures, corrosive fluids, or fluctuating temperatures, where a reliable and secure connection is crucial.↪ The choice of back ferrule size may also depend on specific application requirements, such as operating pressure, temperature range, fluid compatibility, and environmental conditions.

↪ Back ferrules are used in a wide range of industries and applications where leak-tight connections are essential. This includes plumbing, hydraulic systems, pneumatic systems, instrumentation, and process industries.

↪ Depending on the industry and geographic location, specific standards may dictate the sizing and specifications of back ferrules. For example, in the United States, standards from organizations like ASTM or SAE may apply, while in Europe, standards from organizations like DIN or ISO may be more prevalent.

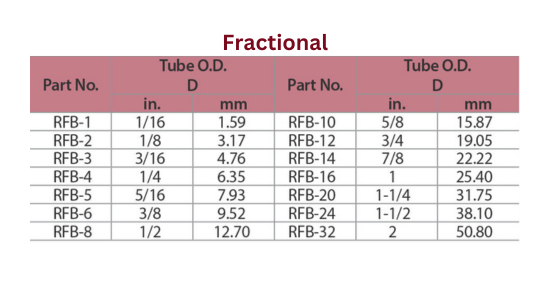

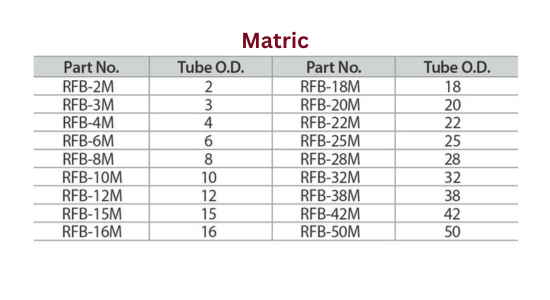

Fitting Sizes & Tube Outer Diameter (OD)

↪ Metric sizes are also prevalent, such as: 4mm, 6mm, 8mm, 10mm, 12mm, 15mm, 18mm, 22mm, etc.↪ Back ferrules sized to match the outer diameter of the tubing they are intended to grip and support. Standard sizes 1/8", 3/16", 1/4", 5/16", 3/8", 1/2", 5/8", 3/4", 1", etc.

Material

↪ Back ferrules are commonly made from materials such as brass, stainless steel, carbon steel, or other alloys.↪ The choice of material depends on factors such as compatibility with the fluid being conveyed, temperature, pressure, and corrosion resistance requirements.

Fractional

Function

↪ Its primary function is to anchor the tubing in place, preventing it from moving or being dislodged when subjected to pressure or vibration.↪ The back ferrule, also known as the anchoring or gripping ferrule, works in conjunction with the front ferrule in a compression fitting assembly.

↪ Positioned behind the front ferrule and tubing, the back ferrule is responsible for gripping and supporting the tubing when compressed against the front ferrule by the fitting nut.

Design

↪ Similar to the front ferrule, the back ferrule is typically cylindrical. It has a tapered inner surface that matches the angle of the fitting body.↪ The outer surface of the back ferrule may have serrations, ridges, or other features designed to grip the tubing securely when compressed.

↪ The material of the back ferrule is chosen for its ability to deform and provide gripping strength without cracking or warping excessively under pressure.

Metric

Maintenance and Replacement

↪ Regular inspection and replacement of worn or damaged back ferrules are essential to maintain the integrity and performance of compression fittings and prevent leaks.↪ Like front ferrules, back ferrules may experience wear over time due to repeated assembly and disassembly of compression fittings or exposure to harsh operating conditions.