Metal Gasket for Male Connector

Metal Gasket For Male Connector

When referring to a male connector for a metal gasket (known as ROM, which stands for Ring Type Joint), it typically indicates a specific type of connection used in high-pressure and high-temperature applications, especially in the oil and gas sectors, have proven to be highly beneficial other critical environments.

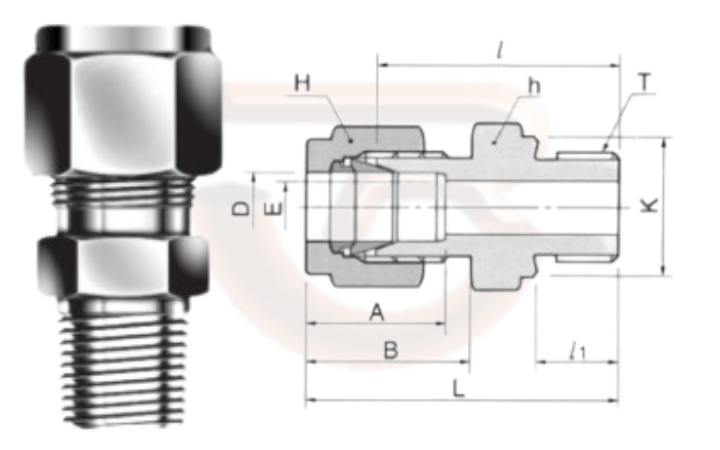

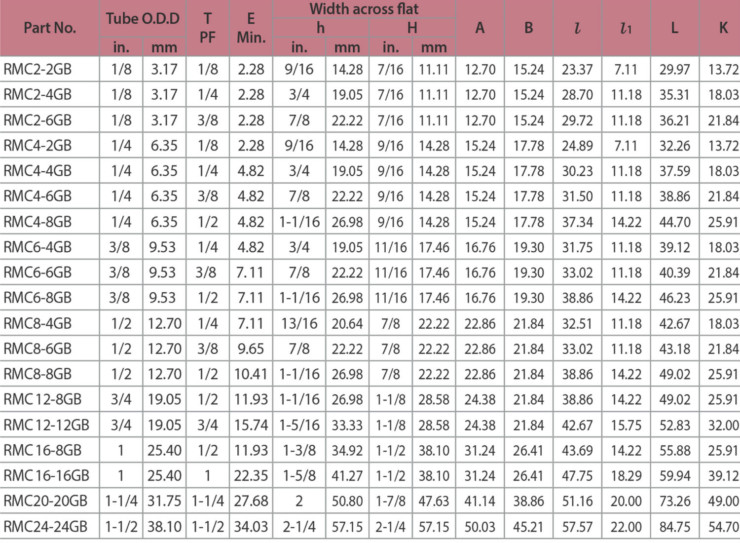

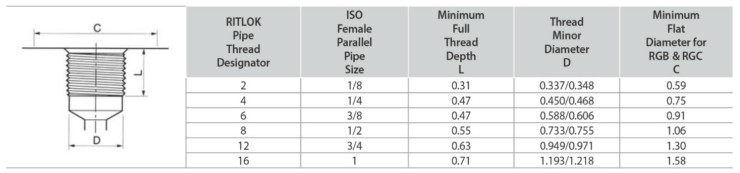

Connects fractional tube to female ISO parallel thread

Features

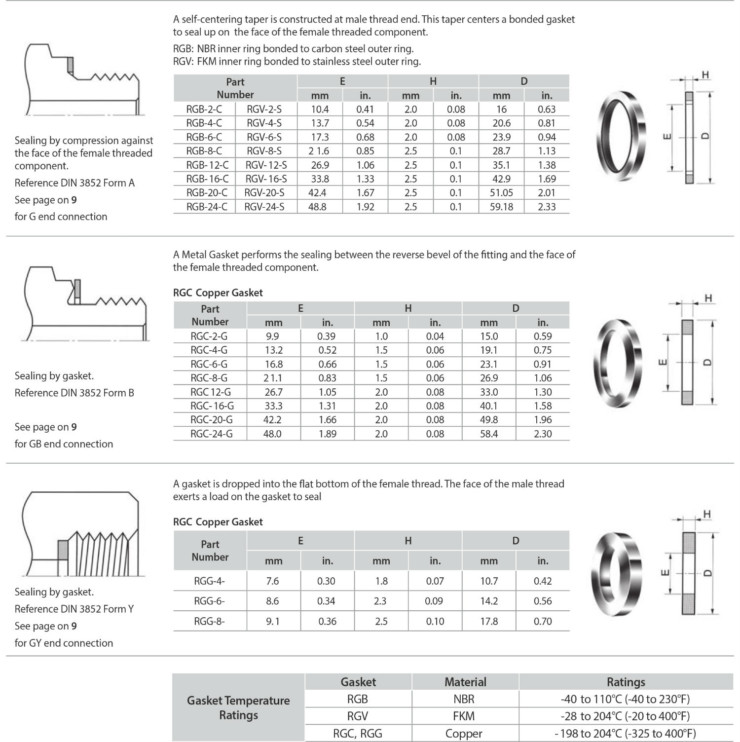

Metal Gasket (Ring Type Joint): The gasket used is made of metal and is often designed as a ring. Ring-type joint (RTJ) gaskets are commonly used in high-pressure sealing applications.Grooved Flange Faces: The male and female connectors feature grooved faces designed to accommodate the metal gasket. The metal gasket fits into the grooves to create a tight seal.

High-Pressure Applications: This type of connection is well-suited for high-pressure and high-temperature applications commonly found in the oil and gas industry.

Applications

Oil and Gas Industry: Male connectors with metal gaskets are frequently used in wellhead connections, pipelines, and other critical applications in the oil and gas sector.High-Pressure Systems: Wherever high-pressure conditions exist, such as in petrochemical plants or chemical processing facilities, metal gaskets with male connectors are employed.

Materials

Metal Gasket Material: Typically made from stainless steel, alloy steel, or other materials capable of withstanding high pressures and temperatures.Connector Material: The male connector may be constructed from materials like stainless steel. The application's specific requirements determine the choice between carbon steel and alloy steel.

Installation

Flange Connection: The male connector is part of a flanged connection. It mates with a corresponding female flange featuring grooves for the metal gasket.Gasket Placement: The metal gasket is carefully placed in the tracks of the flange faces, ensuring proper alignment.

Bolted Connection: The flanges are brought together and secured with bolts, compressing the metal gasket between the male and female flange faces to create a robust and reliable seal.

Considerations

Tightening Specifications: Follow manufacturer specifications for proper bolt tightening procedures to achieve the required pressure seal.Material Compatibility: Ensure the male connector and metal gasket materials are compatible with the substances flowing through the piping system.

Environmental Conditions: To select the appropriate metal gasket material, consider the environmental conditions, including temperature and pressure fluctuations.

Manufacturer's Guidelines: Adhere to the manufacturer's guidelines and specifications to ensure the correct installation and performance of the male connector with a metal gasket.

Note 👍 Male connectors with metal gaskets are critical in applications where extreme pressure and temperature conditions demand a robust and reliable sealing solution. It is crucial to ensure the integrity of the connection by following industry standards and conducting a proper installation.