Non-Positionable SAE Male Connector RMCS-U

Non-Positionable SAE Male Connector RMCS-U

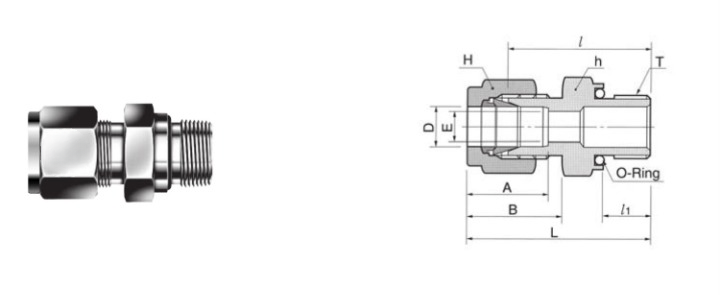

↪ The Non-Positionable SAE Male Connector, designated as RMCS-U, is a type of fitting commonly used in hydraulic systems to create a secure connection with SAE straight threads.↪ This connector is designed to connect tubing or hose to a component with SAE straight threads. It's non-positionable, meaning once it's tightened, it cannot be rotated or repositioned easily.

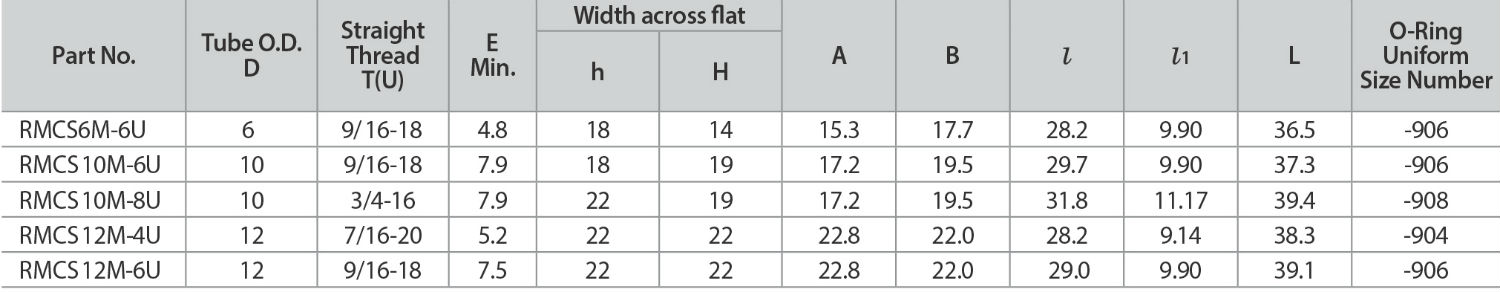

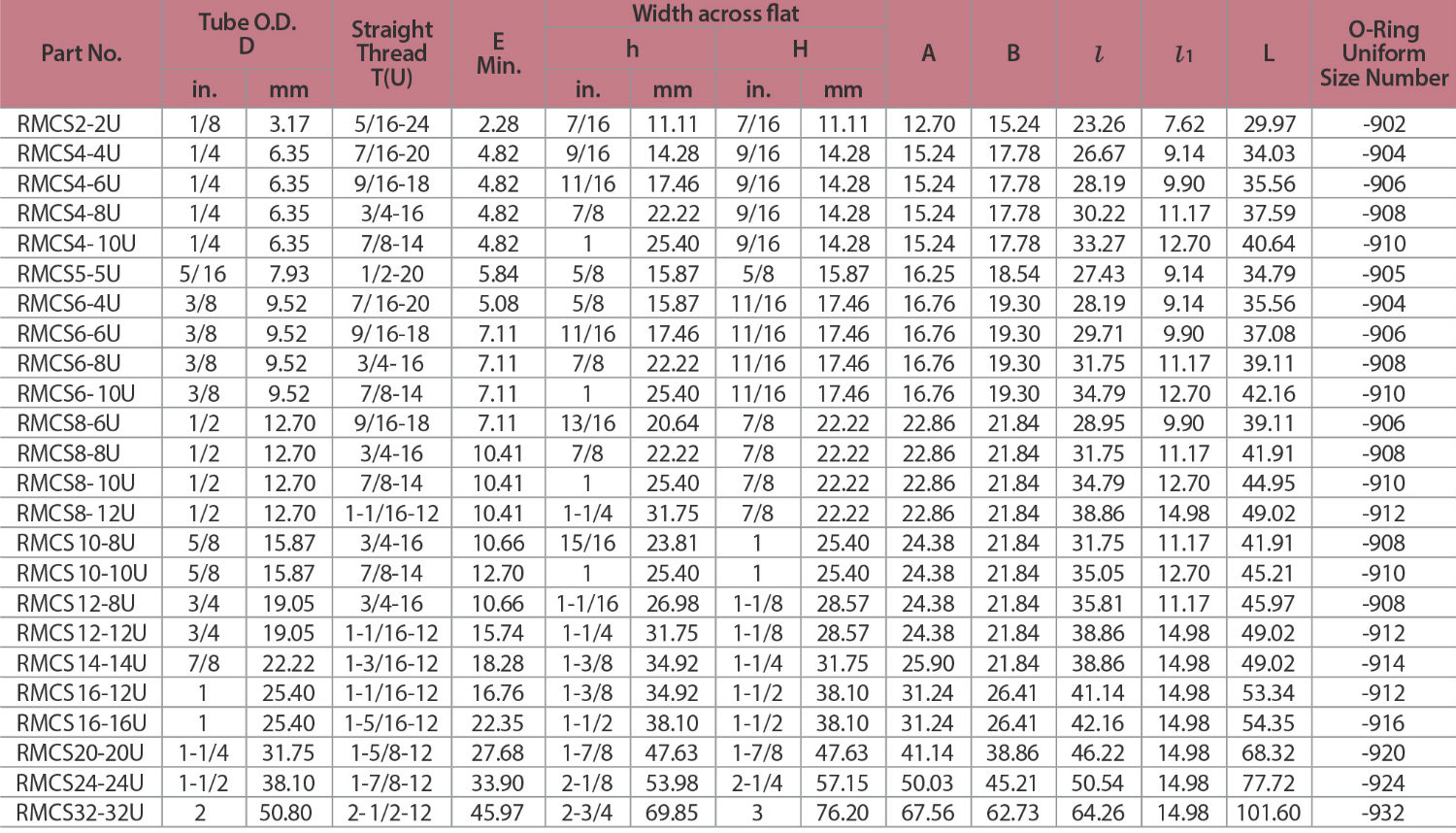

➢ 1/8", 1/4", 3/8", 1/2", 3/4", 1", 1-1/4", 1-1/2", 2" (inch sizes)

Join a fractional tube to an SAE straight thread boss

➢ Applications: These connectors are commonly used in hydraulic systems for machinery, equipment, and vehicles. They are suitable for high-pressure hydraulic lines, hydraulic cylinders, pumps, and valves.

➢ Sizes: RMCS-U connectors are available in various sizes to accommodate different SAE straight thread specifications. Common sizes include 1/8", 1/4", 3/8", 1/2", 3/4", 1", 1-1/4", 1-1/2", and 2" for inch sizes.

➢ Sealing Mechanism: These connectors typically utilize an elastomeric O-ring or a metal-to-metal seal to create a leak-proof connection. The sealing mechanism ensures reliable performance under high-pressure hydraulic applications.

➢ Installation: Installation of RMCS-U connectors involves threading the male connector into the mating female port until it forms a secure connection. Proper tightening ensures a leak-proof seal without the need for additional positioning adjustments.

➢ Maintenance: Regular inspection of the connector and O-ring (if applicable) is recommended to ensure proper sealing and prevent leaks. Connectors should be inspected for signs of wear, damage, or corrosion, and O-rings should be replaced if necessary.

➢ Design: The connector is designed with SAE straight threads, which conform to the standards set by the Society of Automotive Engineers (SAE). Once tightened, these straight threads provide a secure connection without the need for rotation or positioning adjustments.

➢ Material: RMCS-U connectors are typically made from materials such as steel, stainless steel, or brass, depending on the application requirements. The choice of material is based on factors such as compatibility with the hydraulic fluid, operating conditions, and environmental considerations.

Connect a metric tube to an SAE straight thread boss