O-Seal Straight Thread Connector RMC-UO

O-Seal Straight Thread Connector RMC-UO

↪ This is a connector designed for straight threads and uses O-rings to create a seal. It's suitable for applications where straight threads are used, and the O-ring provides a reliable seal.↪ The O-Seal Straight Thread Connector, designated as RMC-UO, is a fitting commonly used in fluid systems to create a secure connection with straight threads while ensuring a reliable seal with an O-ring.

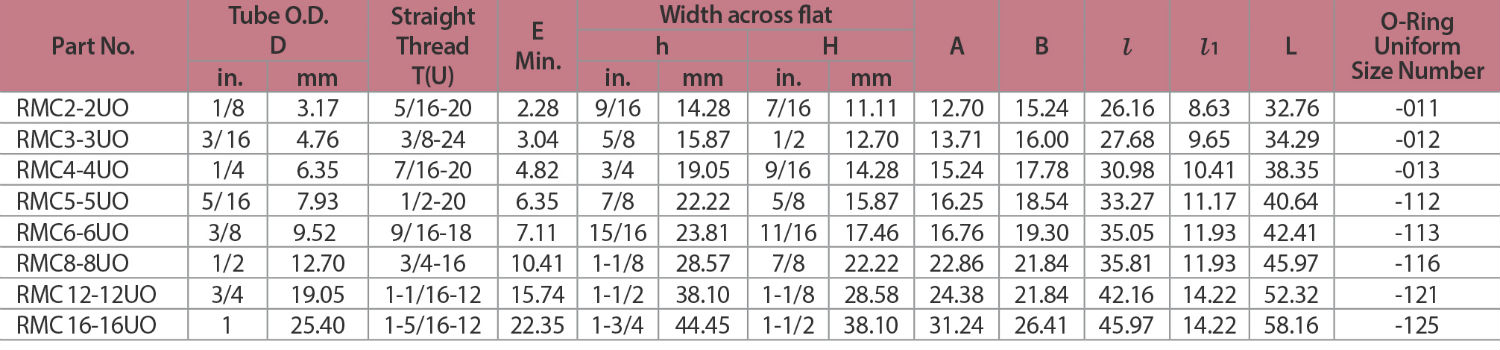

➢ 1/8", 1/4", 3/8", 1/2", 3/4", 1", 1-1/4", 1-1/2", 2" (inch sizes)

➢ M6, M8, M10, M12, M16, M20, M24, M30 (metric sizes)

Attach a fractional tube to a female straight thread

➢ Design: The connector is designed with straight threads, which means the lines run parallel to the axis of the fitting. This design allows for a straightforward installation process and facilitates a secure connection.

➢ Maintenance: Regular inspection of the O-ring condition and torque checks on the fittings are recommended to maintain the integrity of the seal and prevent leaks. O-rings should be replaced if signs of wear or damage are detected.

➢ Installation: Installation of RMC-UO connectors involves threading the connector into the mating component until it forms a secure connection. Proper tightening ensures that the O-ring is adequately compressed to create an effective seal.

➢ Sealing Mechanism: The RMC-UO connector incorporates an O-ring seal. The O-ring is positioned within a groove on the connector and is compressed when the fitting is tightened. This compression creates a tight and leak-proof seal between the connector and the mating component.

➢ Sizes: RMC-UO connectors are available in various sizes to accommodate different tubing or thread specifications. Standard sizes include 1/8", 1/4", 3/8", 1/2", 3/4", 1", 1-1/4", 1-1/2", and 2" for inch sizes, as well as metric sizes like M6, M8, M10, M12, M16, M20, M24, and M30.

➢ Material: These connectors are typically made from materials such as stainless steel,ss, or other corrosion-resistant materials. The choice of material depends on factors such as compatibility with the fluid being conveyed, environmental conditions, and application requirements.

➢ Applications: These connectors are widely used in hydraulic systems, pneumatic systems, fluid transfer systems, and other applications where a reliable and leak-proof connection is essential. They are suitable for high-pressure and high-temperature environments, making them versatile components in various industries.