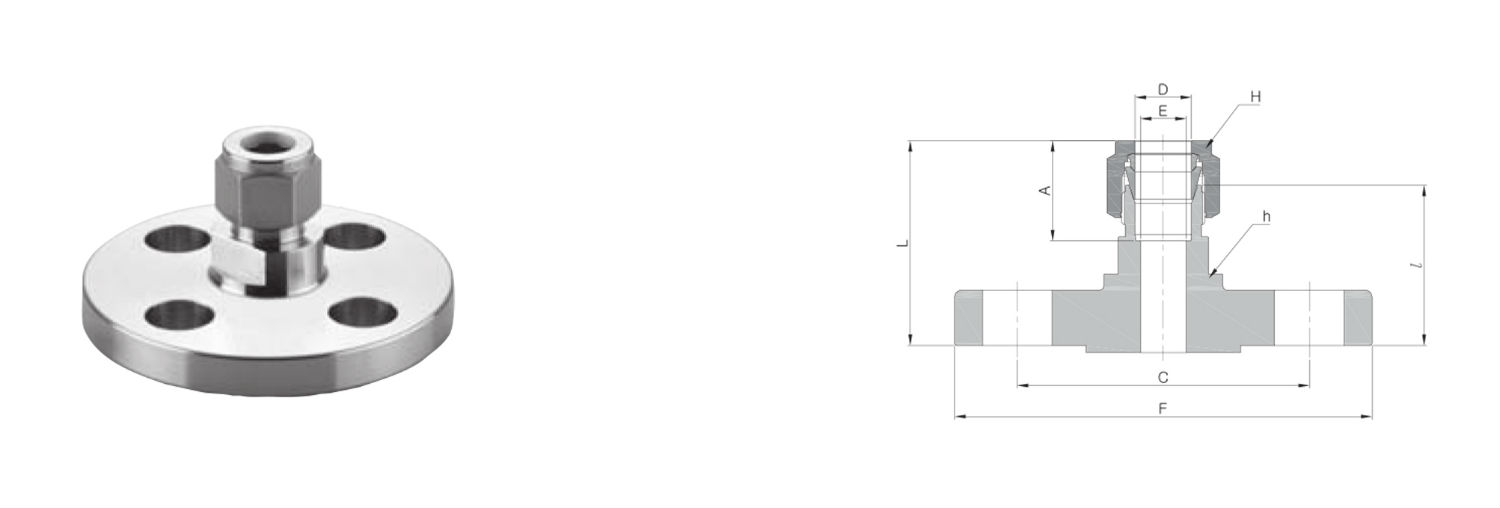

RFP Flanges ANSI B16.5 RF

ANSI B16.5 RF Flanges

↪ These flanges conform to the ANSI (American National Standards Institute) B16.5 standard.↪ANSI B16.5 RF flanges are widely used in industries following ANSI standards, such as oil and gas, chemical, and power generation.

↪RF (Raised Face) denotes the type of flange facing, which features a raised surface around the bolt holes to accommodate a gasket for a tight seal.

➢ ANSI B16.5 RF Flanges refers to a specific type of flange design that conforms to the standards set by the American National Standards Institute (ANSI) under the B16.5 specification.

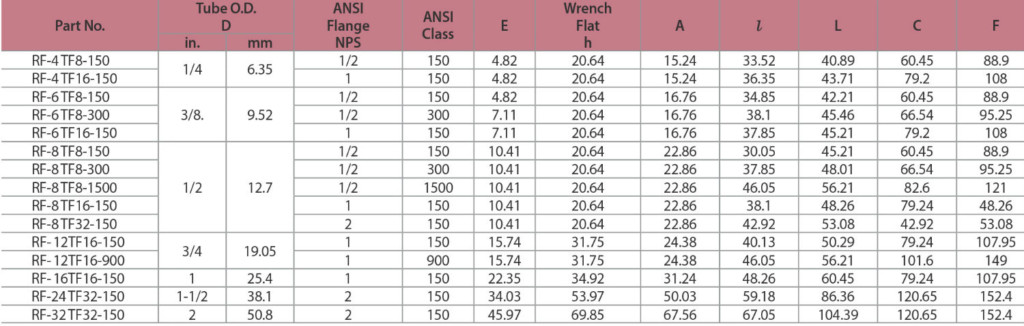

Connect ANSI flanges to fractional tubes with pressure class ratings from 150 to 2500 for NPS 1/2 inch.

➢ Standard Compliance: ANSI B16.5 RF Flanges adhere to the guidelines outlined in the ANSI B16.5 standard, which covers pipe flanges and flanged fittings for size NPS 1/2 through NPS 24 for various pressure ratings.

➢ Bolt Holes: ANSI B16.5 RF Flanges are characterized by a specific arrangement of bolt holes around the perimeter of the flange. The number and diameter of bolt holes depend on the flange size and pressure rating.

➢ Pressure Ratings: ANSI B16.5 RF Flanges are available in various pressure classes, ranging from 150 to 2500 pounds per square inch (psi), indicating their ability to withstand different levels of internal pressure within a piping system.

➢ Materials: These flanges can be manufactured from a variety of materials, including carbon steel, stainless steel, alloy steel, and other suitable materials, depending on the requirements of the application and the media being transported.

➢ Applications: ANSI B16.5 RF Flanges are widely used in industries such as oil and gas, petrochemical, chemical processing, power generation, and water treatment. They are employed to connect pipes, valves, fittings, and other equipment in piping systems while ensuring a secure and leak-free connection.

➢ Raised Face (RF): The RF designation indicates the facing type of the flange. RF flanges feature a raised surface around the bolt holes and the flange perimeter. This raised face provides a mating surface for the gasket, allowing for a tight seal when the flange is bolted to another mating flange or equipment.

↪ NPS 1/2 (Nominal Pipe Size 1/2) ❂ NPS 3/4 ❂ NPS 1 ❂ NPS 2 ❂ NPS 3 ❂ NPS 4 ❂ NPS 6 ❂ NPS 8 ❂ NPS 10 ❂ NPS 12 ❂ NPS 14 ❂ NPS 18 ❂ NPS 20 ❂ NPS 24

↪ 1/2 inch (DN15) ❂ 3/4 inch (DN20) ❂ 1 inch (DN25) ❂ 2-inch (DN50) ❂ 3-inch (DN80) ❂ 4-inch (DN100) ❂ 6-inch (DN150) ❂ 8-inch (DN200) ❂ 10 inch (DN250) ❂ 12 inch (DN300) ❂ 14 inch (DN350) ❂ 16 inch (DN400) ❂ 18 inch (DN450) ❂20 inch (DN500) ❂ 24 inch (DN600) ❂ 30 inch (DN750) ❂ 36 inch (DN900) ❂ 42 inch (DN1050) ❂ 48 inch (DN1200)