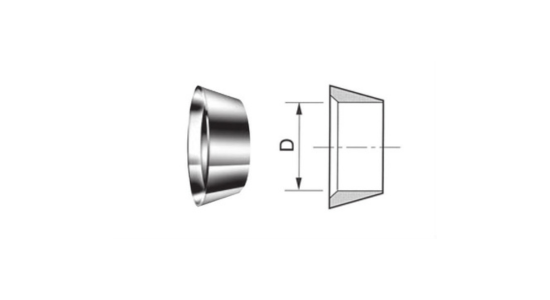

Front Ferrule

Front Ferrule:

↪ The front ferrule is a crucial component in compression fittings used to create leak-tight connections in tubing systems.↪ It is responsible for creating a seal between the relevant body and the tubing when compressed against the fitting body by the nut.

↪ A front ferrule, also known as a sealing ferrule or compression ring, is the ferrule positioned closest to the fitting nut in a compression fitting assembly.

Function:

↪ The compression fitting is assembled, the front ferrule is positioned in front of the tubing, between the tubing and the fitting body.↪ The front ferrule, also known as the sealing ferrule or compression ring, plays a critical role in establishing a leak-tight seal between the tubing and the fitting body.

↪ The compression force applied by the nut causes the front ferrule to bite into the surface of the tubing, creating a secure and reliable connection that prevents fluid or gas leakage.

↪ As the fitting nut is tightened onto the fitting body, the front ferrule is compressed against the tubing, deforming slightly to create a tight seal between the ferrule, tubing, and fitting body.

Design:

↪ Front ferrules are typically cylindrical and have a tapered inner surface that matches the angle of the mating surface on the fitting body.↪ The outer surface of the front ferrule may have serrations, ridges, or other features designed to grip the tubing securely when compressed.

↪ The material of the front ferrule is chosen for its ability to deform and create a reliable seal without cracking or deforming excessively under pressure.

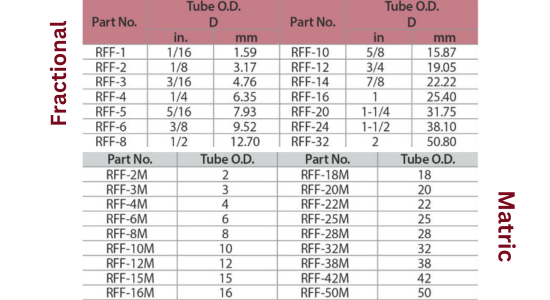

Tube Outer Diameter (OD):

↪ Metric sizes: 4mm, 6mm, 8mm, 10mm, 12mm, 15mm, 18mm, 22mm, etc.↪ Front ferrules sized to match the outer diameter: 1/8", 3/16", 1/4", 5/16", 3/8", 1/2", 5/8", 3/4", 1", etc.

Fitting Sizes:

↪ Metric sizes: 6mm, 8mm, 10mm, 12mm, 15mm, 18mm, 22mm, etc.↪ Standard dimensions for compression fittings: 1/8", 1/4", 3/8", 1/2", 3/4", 1", etc.

↪ Front ferrules wall thickness come in different to accommodate variations in tubing. This ensures a proper seal and secure connection. Wall thicknesses include standard, heavy, and extra-heavy.

Fractional and Matric

Material:

↪ Front ferrules are made from various materials, including brass, stainless steel, carbon steel, or other alloys.↪ The choice of material depends on factors such as compatibility with the fluid being conveyed, temperature, pressure, and corrosion resistance requirements.

Applications:

↪ They are particularly suitable for applications involving high pressures, corrosive fluids, or fluctuating temperatures, where reliability and integrity are paramount.↪ The choice of front ferrule size may also depend on specific application requirements, such as operating pressure, temperature range, fluid compatibility, and environmental conditions.

↪ Front ferrules are used in a wide range of industries and applications where leak-tight connections are essential, including plumbing, hydraulic systems, pneumatic systems, instrumentation, and process industries.

↪ Depending on the industry and geographic location, specific standards may dictate the sizing and specifications of front ferrules. Ex- in the United States, standards from organizations like ASTM or SAE may apply, while in Europe, standards from organizations like DIN or ISO may be more prevalent.

Maintenance and Replacement:

↪ Front ferrules may wear out over time due to repeated assembly and disassembly of compression fittings or exposure to harsh operating conditions.↪ Regular inspection and replacement of worn or damaged front ferrules are essential to maintain the integrity and performance of compression fittings and prevent leaks.